Anytime a project manager inquires about the costs of development, the main question they all do is about the total cost of the plastic injection mold. This is not an unusual occurrence since the finished mold represents a large portion of the overall budget on the upfront expenses that need to be paid before starting a production cycle. There are many takes on the factors that decide the final costs of a mold. It’s nearly impossible to pinpoint a single reason for it. Over the next few lines, we are going to study a few variables that can have some impact for the sake of putting the information out there. Let’s take a look at them:

Table of Contents

Toggle· The Choice of Metal

Some plastic injection molding projects have such short runs that managers make the call of creating the mold using aluminum. It’s a natural course of action given the logistics of the project and the fact that aluminum is inexpensive. The main drawback of this decision could be the instance where the product becomes a success. If that where the case, the company tasking the mold will have to spend money creating a sturdier mold for a planned run of many years until the product is upgraded or is replaced.

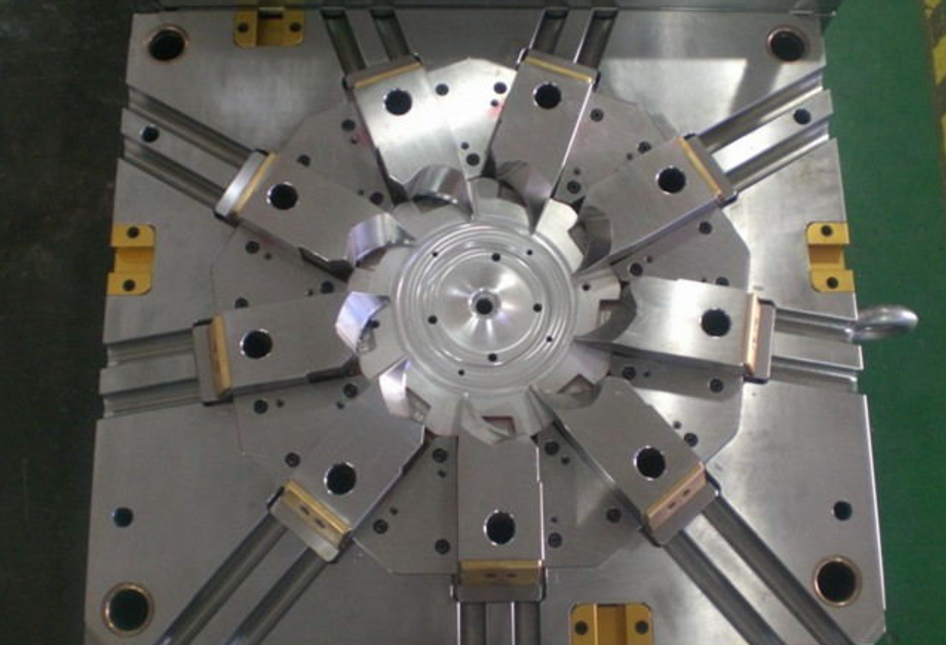

· The Cavities

Fewer cavities on a mold demand less tooling and are cheaper in the end. Experienced molders in the business can optimize cavitation’s in the mold to achieve high levels of productivity. Most manufacturers recommend creating one mold for each part you plan to build. True professionals can keep costs low by creating “family molds” that gather various cavities for different parts. The downside is that if the tooling is not right, these molds will create weak products with low quality.

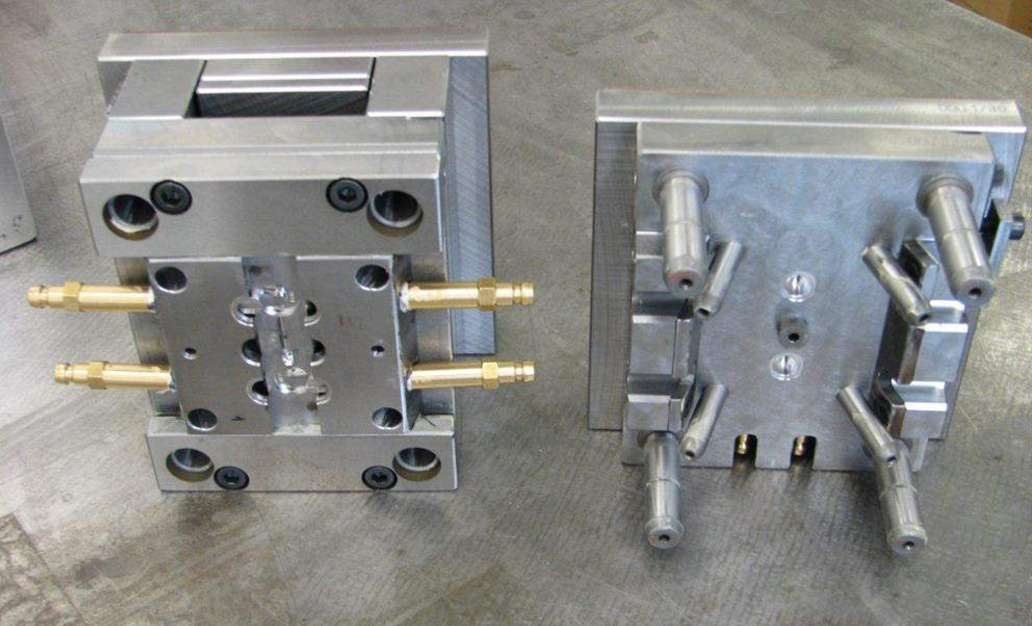

· The Base

The base is the part of the mold that holds all the cavities, the inserts, and all the components in conjunction. The final costs of a base are related to the size of the mold and the type of metal used to create as well as all the customizing it needs to perform as expected. Mold bases are always presented in relatively standard sizes, but they are continuously modified and machined to fulfill the requirements of each project they are used.

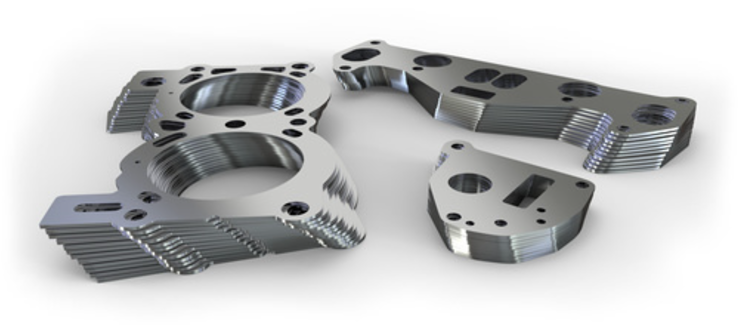

· The Core

All molds are customized until they deliver the desired result asked by the client. Manufacturers have their tooling departments ready to place the cores, the cavities, the ejectors, and the coolant lines where they are needed. As we stated in the first part of the article, all molds are made of metal so if the client needs sturdier materials the prices will go up. The harder the material requested for the core, the more expensive the overall cost of the mold will be.

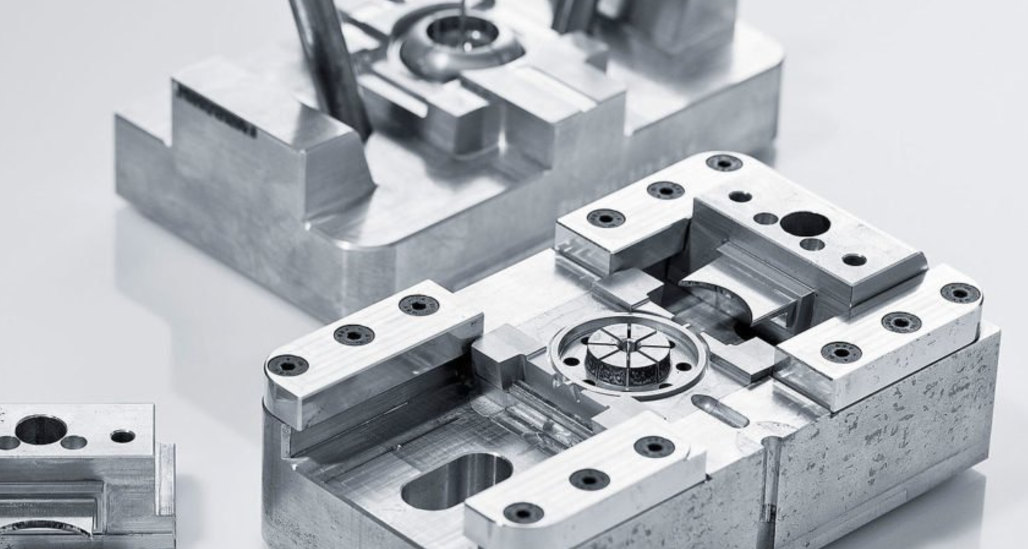

· The Complexity

This is a moment for in-depth analysis on the client’s end. The considerations about the complexity of a project are always a cause for friction between them and manufacturers since some clients have high expectations about the ability of the manufacturer to deliver a top-quality finished product on a low budget. Little details such as the number of undercuts or aspects related to the surface of the product can contribute to the level of complexity of each project. As you can expect each detail adds to the final cost.