Plastic Injection Molding Services incorporate processes that enable the industry or service provider to develop high-end parts in large quantity and that too quickly and with precision and accuracy. Since you are working with the prototypes thus it reduces the labour cost. Complex and complicated designs can be achieved or made efficiently and can work with wide variety of plastic materials to develop a flexible but long-lasting end product.

Table of Contents

ToggleProcess of Plastic Injection Molding Services

Plastic injection molding Services are used to create unique end product and that too mass production of the same based on the design given by the company. The results are reliable and quality and accuracy of product is high. Process of molding is:

- The process starts with engineering personnel designing a specific mold for some purpose.

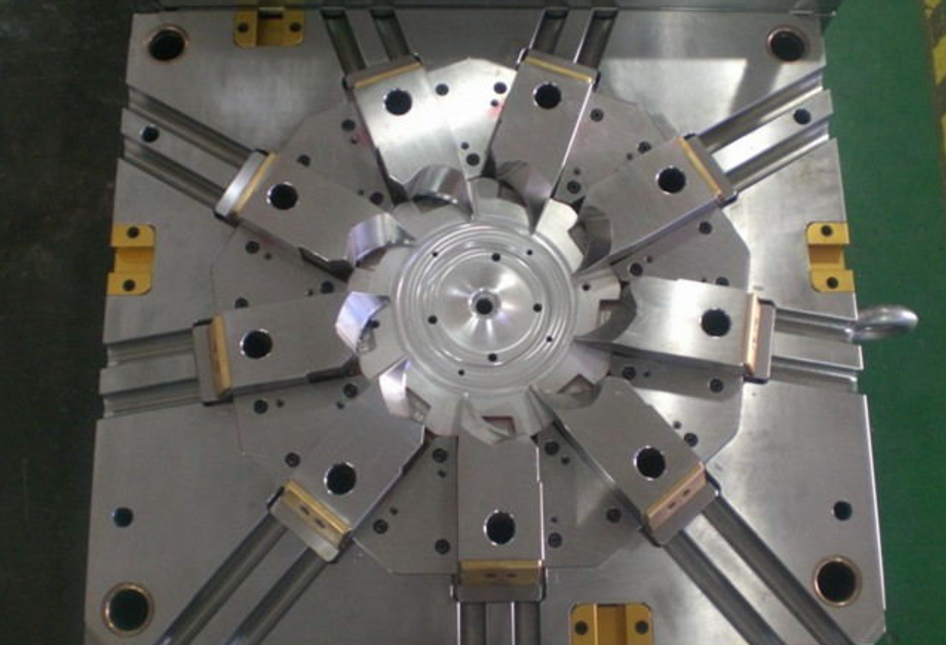

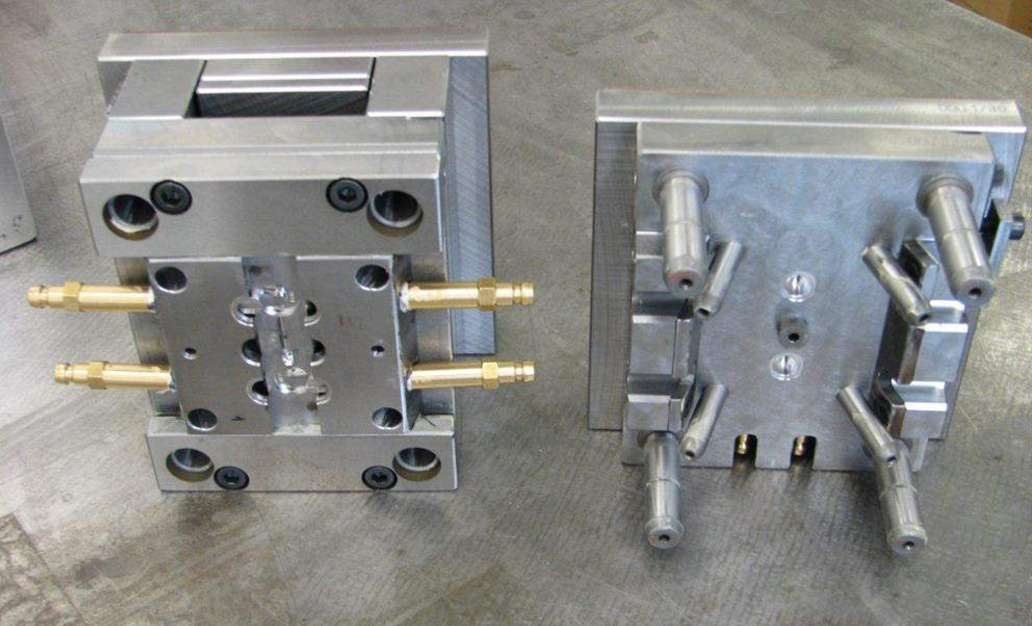

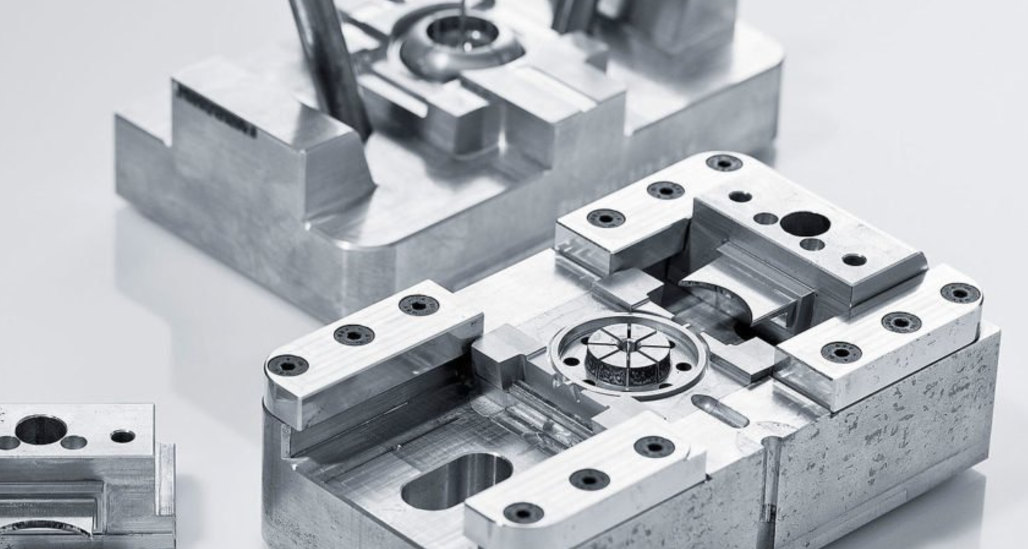

- This design is then given to the toolmaker to get a mold created which is generally made out from steel or aluminium.

- The mold is then machined into precision and

- Then used for injecting the molten plastic into the above mentioned mold.

- Now here the molten plastic cools down and solidifies into a part.

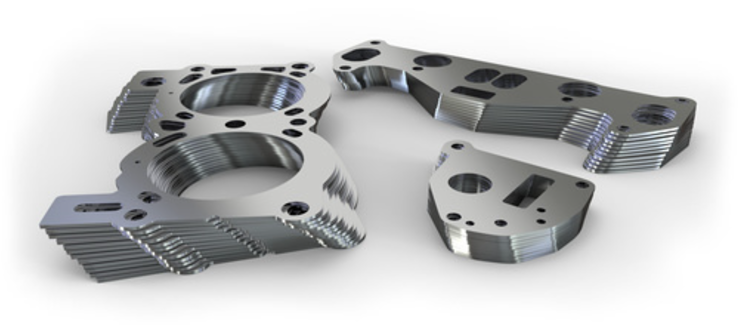

- To form the mold 3D printers or CNC machines are used.

Advantages of Employing These Plastic Injection Molding Services

There are majorly three main benefits that come to mind when we talk about Plastic Injection Molding Services. They are:

- After the initial designing and mold has been created using the same, the manufacturing cost is quite reasonable when price per unit is seen.

- The process is very efficient as there is minimal wastage of raw material and time, and also the scrap that is collected in the process can be recycled.

- Since same design is used to do mass production there is consistency in the products, which is good for establishing brand value and is good as parts can be interchanged. Consistency brings in cost-saving.

Things you should consider before employing Plastic Injection Molding Services

Before employing these services you should always think whether they are suitable for your manufacturing processes. Some of the things that you must consider when you are designing a part using these services are:

- Design and Provisions:Whenever we talk about designing, 3D printers are used almost in all cases to develop a prototype, you have to see whether the product you plan can be created using 3D printing technique or not. You should also consider the mold tool as well. Also try and make as many prototypes as possible so that the design of the part you want is accurate and precise. It would be loss of money and time if you go for 10,000 pieces in first run itself.

- The Tools used for Injection Molding:The tools which are used for Injection Molding can be seen as a drawback and costly affair by many as this is an initial cost and that too high. But think that if the mold that you created using these tools is right then only you will be getting a precise and accurate part. Changing the design of the part afterwards is nearly impossible and most of the times you have to start over. In some cases extra metals can be welded into the design but that requires highly-skilled personnel and is very time consuming as well.

- Size of the mold and Wall Thickness:If you want to achieve perfect injection molding , the mold should have thickness of all walls uniform. If it is not so and are thick then sinkholes and other errors can occur in the design of the part. If the walls are too thin of the mold it will make ways for gaps in the end product, as whole mold is not properly filled. 4mm thickness of wall is a safe play and anything below 1mm will be a waste and will cause trouble in molding process. Size of the mold is also a major thing to consider as the final product can sometime end up being larger than the mold size. This generally happens during 3D printing or CNC Machining design used for molds. Parts that are 3D printed should be put together to get the desired size.

These pointers you must consider before employing Plastic Injection Molding so that the process is hassle free and there is as less wastage of time, raw material and money as much is possible.

Conclusion

Plastic Injection Molding Services are the latest technology which has revolutionized the designing and manufacturing processes. The designs thought by the engineers can be developed or created using these techniques to the greatest precision and accuracy possible. It has greatly reduced the labour issues and raw material wastage that would happen when traditional manual method was used. It has brought on a new- era in manufacturing.