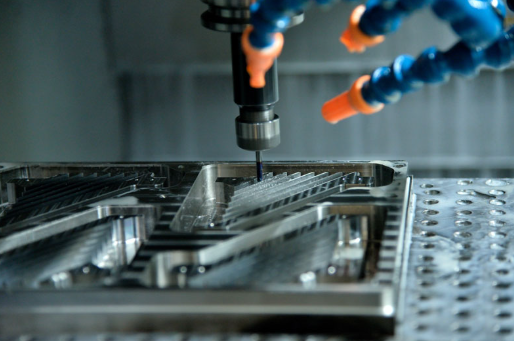

Cavitation is a process inherently related to plastic injection molding. The easiest way to explain it would be to define it as the management of on the number of cavities that are used by a molding machine in each press cycle. The more cavities are used, the lower the costs of casting individual parts. Cavitation is also an influent factor often affected by budget concerns. The deformation of the plastics and resins used to cast molds when these materials crystalize on amorphous phases as they get stronger after being long stretched or exposed to heat can bring forward big loses if you don’t manage the logistics related to cavitation before starting production.

Table of Contents

ToggleCavitation as a Logistics Procedure

Molding plastic production has decreased the cost of manufacturing a lot of parts for some time now, even though the process to bring a prototype to life still needs to be cost-efficient. Handling the budget mass-produce anything needs to be budgeted and managed on promptly fashion. Any manufacturer will tell you that the best way to go to get your products delivered more quickly is to increase the cavitation on your press cycles to get more products out in less time. While this holds true for the sake of the readiness of the shipment, sometimes quality will be sacrificed in the process as well as durability. Is the job of the manufacturer to find a positive balance, that favors the standards needed for the product?

The Business Angle of Cavitation

One of the main factors influencing this business strategy is also the fact that a high number of cavities per press cycle deliver the pieces at cheaper prices but it also makes the manufacturer’s equipment work much less and with less effort. The materials used to cast the molding process are also better distributed, and fewer performance problems come along. Since the proper cavitation is meant to bring forward quick results, other aspects related to the whole design process tend to be more expensive, especially if they are handled by the manufacturer himself. Tooling and casting the cavity mold will be quite expensive, but depending on your choice of manufacturer it will be compensated by the individual cost of single units.

Cost, Materials and other Considerations

Since the maintenance cost of multi-cavity mold machines it’s also very costly, manufacturer always aims to get the most out of them before their periodical revisions. One of the greatest perks of working long-term contracts is that manufacturers retain the specs of each part on their archives. Going back to them to get a re-stock will yield much better results and a better deal. Since most manufacturer work with software that handles the same specs is not unusual for a client to bring their own 3D design. The manufacturer can choose to tweak it for an extra fee or simply deliver the part as requested. Since testing is involved in the process, you will also need to consider the materials you can afford to cast the plastics parts you need to fix anything performance-wise.