Nowadays, product designing is continuously evolving. The popularity of additive manufacturing like 3D printing and CNC machining has changed the way products are made and their turnaround time. The competition for companies to produce unique designs is stiff. And the expectations on customization from the clients are more demanding than before. What works with the market back then will not work anymore. With all these demands at hand, product developers are now veering away from mass production and moving towards low volume manufacturing.

Table of Contents

ToggleWhat is low volume manufacturing?

Low volume manufacturing depends on the process, the materials and tooling being used, it generally refers to manufacturing products from 50 to 100,000 volume. This type of production can be used by companies of any size, from small start-ups to established entrepreneurs.

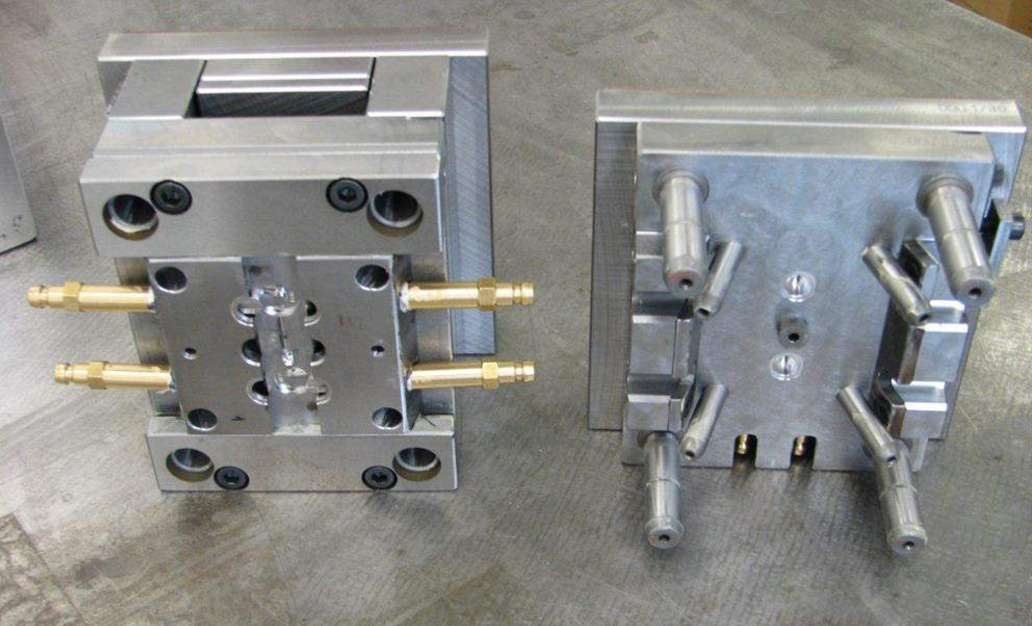

There are different cases and conditions that may need low volume manufacturing in various industries. It can be applied for pre-high-volume production. Before venturing into high-volume production, there is a phase between the prototyping and final stage in production. Low volume production is used to produced small units through prototyping hard tooling.

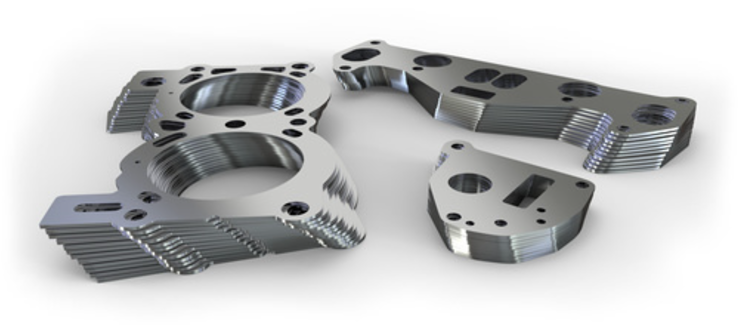

Low volume manufacturing is also used in repair or replacement of parts. Sometimes, some parts are no longer available anymore. The only way to repair the machine is to customize a part using additive manufacturing or CNC machining. When the prototyping phase is completed, there is a need for low volume manufacturing to produce the parts for tooling.

The Top Benefits of Low Volume Manufacturing

#1 It can help you save money

Contrary to the preconceived notion that high volume production always saves money, that is not always the case. It may work when you are doing grocery shopping from warehouse stores but not when it comes to manufacturing. The amount you will spend on each unit is dependent on the materials used.

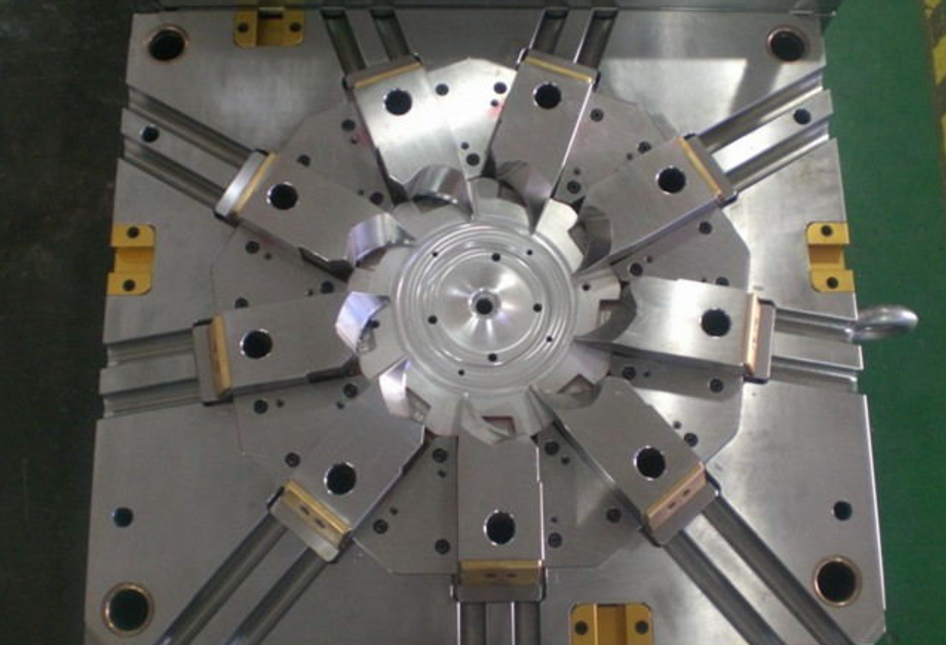

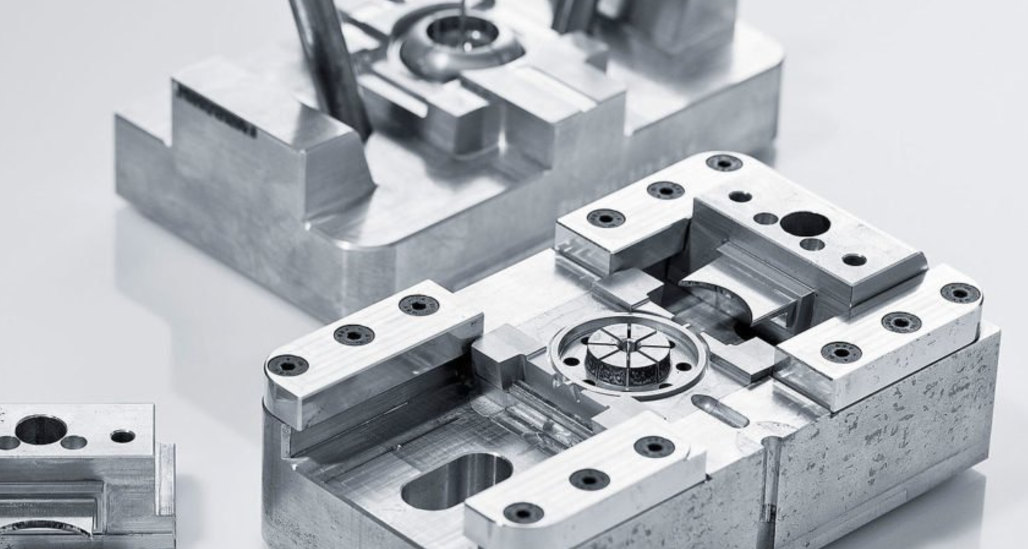

One classic example is steel. The type of steel used for tooling can range from alloy and carbon steels. These are hard, resistant to scratches and scrapes, and difficult to deform. Steel tooling is an expensive investment. Companies will have to make huge investments if they use this material for mass production, especially when injection molding or die casting will be used. It will need a new process for large-scale production. The tool needs to be hardened using heat treatment and in other cases, coated with the use of physical vapor deposition (PVD).

In this case, low-volume manufacturing is the best option to avoid significant investment. If the final part or part of the tool does not withstand stress, it will be more economical to use less durable steel to machine it. You can still have a high-quality part and will save money.

Large volume production often imposed on a minimum order to offset the investment on production and operation costs. Because low volume production has lower overhead, it can make products without minimum order. Companies who are looking to produces a product or part in small quantities can opt for this production type.

#2 It can give companies design flexibility

Rapid prototyping, additive manufacturing, and low-volume manufacturing is the best option if you are looking for design flexibility. Because the products are manufactured in small quantities, it will not impact the whole order if the client wants to change their design. This can allow the company to perfect the product before it can reach the intended market.

During testing, low volume manufacturing will allow further refinement from consumer feedback. You can also have the product made in multiple variations, which can be a basis for testing. Companies can get which feature of the product is the most popular among the consumers, and they can refine these features on the following product. They can also provide an advantage to the company to target a particular niche.

#3 Products can reach the market faster

Being the first to market a unique product is essential for companies due to stiff competition. The timing can make a difference between failure and success. Competition and the fickle market increase the pressure among designers and developers to create high-quality and one-of-a-kind products. When the manufacturing support is made for low-volumes, there is a shorter lead time which will allow the product to hit the shelve faster.

For this reason, companies can capitalize on short-lived fads and consumer trends.

#4 It presents an option for bridge production

Even if you want to go for mass production, you can use low volume manufacturing as a bridge production between prototyping and the full-scale production phase. Companies can get their products to the market faster and will allow them to convert their ideas into products. This will not be possible with other high-volume manufacturing because of higher cost and longer production time. Bridge production allows product improvement too.

The practice of using low-volume manufacturing has many benefits. It can reduce risk, reduce the time for the product to reach the market, saves costs, and enable flexibility on design. It will continue to evolve and create benefits for many companies in the future.