Rapid tooling can be understood as the combination of conventional tooling practices and modern rapid prototyping techniques. This combination can result in the building of the mold quickly and with high perfection. This is one of the most popular processes today which are mostly used in preparing the parts of functional models by using CAD data. It takes very little time and lowers cost when rapid tooling and CAD are combined for producing functional parts.

Compared to most of the traditional machining methods, rapid tooling takes very little time and cost. This is the main reason rapid tooling is becoming very popular and common in the industry. More than anything, this rapid tooling can be considered as a channel for producing injection molded parts.

Table of Contents

ToggleSuitable for huge volumes

This rapid tooling technology sometimes makes use of Rapid prototyping models for the pattern. In some cases, it makes use of Rapid Prototyping services. These are used mainly for limited quantities of production. One thing to remember here is expenses and tooling costs will be fair enough only when there is a huge volume of production.

Hence we need to find a solution for this and it is nothing but rapid tooling. This helps in making the production process quicker and cost-effective as well. Even when there is a small manufacturing quantity, there is nothing to worry about since rapid tooling can make it cost-effective.

There is always a demand for intermediate tooling for helping out in the production of small quantity prototypes. This is also required for functional tests that come in the product development cycle. They produced small volumes are mostly utilized in marketing samples. They are also utilized in evaluation processes. The small quantity of manufacturing or sample is very useful in the production process design as well. These are the main reasons, behind the popularity of rapid tooling. Today it has become very important in the production or manufacturing industry.

Why rapid tooling?

You can list out plenty of advantages of rapid tooling. There are two most important reasons for adopting this rapid tooling technology and they are

- When rapid tooling is used, tooling time becomes much shorter compared to conventional tool

- Other than that, you need not spend too much on the tooling cost. Rapid tooling helps in reducing the tooling cost compared to the conventional tool

But there is one challenge which the manufacturing industry is facing in rapid tooling and that is nothing but the tool life. Yes, if you compare the tool life of the tools generated by rapid tooling with the conventional tools it is much less. But when you consider tolerance, it is much wider in comparison to that of conventional tools.

Rapid Tooling and its benefits

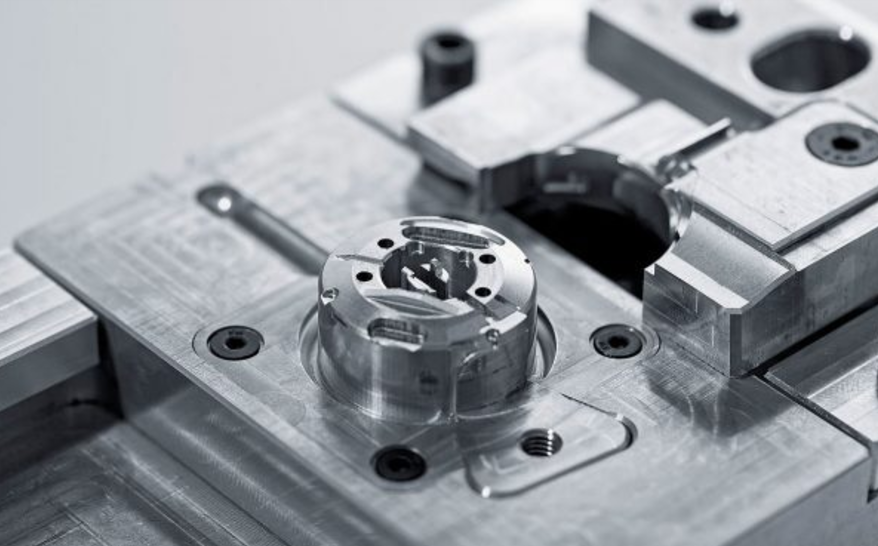

Rapid tooling is a process that is in use for building core and cavity inserts. Here it is done in the form of products via utilizing rapid prototyping technology. There are a lot of merits we can list out for rapid tooling.

- By using rapid tooling it is possible to bring the product into the market much earlier than expected

- Customers can get the product for lesser prices when compared to the result of mass production. So, products from rapid tooling are much cheaper than that come from mass production and injection tools

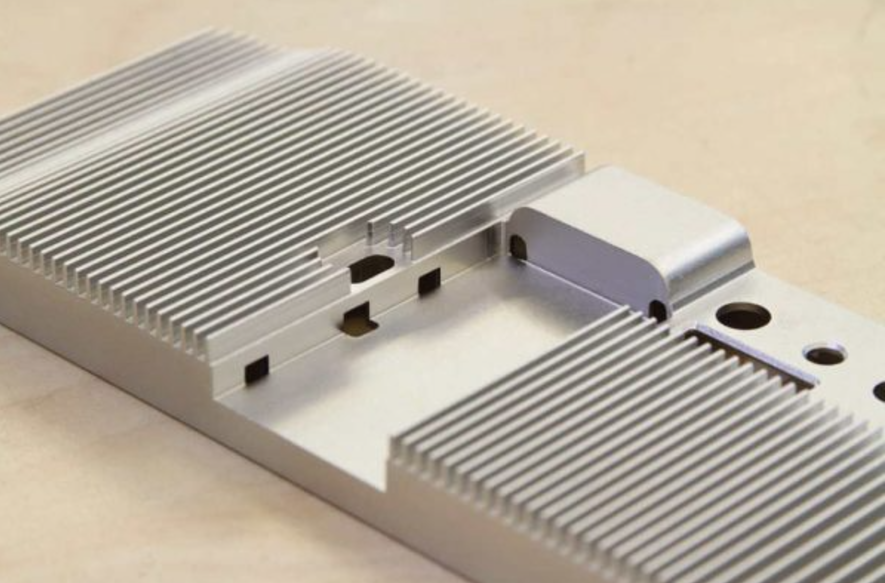

- You can make use of a wider range of materials when you are producing the products from rapid tooling

- Rapid tooling reduces the time as well as the cost of production

- This is mainly in use for specific and small quantity needs such as prototyping

- Rapid tooling is very useful in troubleshooting already existing products

- Today rapid tooling is in use even in the creation of molds mainly for commercial operations. The main reason behind this is, the time lag is very less between prototyping actual production

Apart from these, alternate methods demand precious time along with resources. Hence rapid is a much quicker option for producing required products. This is allowing companies to produce all kinds of commercial products within the planned time and as per their schedules.

Additional benefits

The best thing about rapid tooling is it comes with all the necessary customizations required for personal applications. There is no need to worry about error measurements and go through tedious trials. In this technology, there is a place for putting the design completely through a specific CAD program. At this stage, you will get all the chance for personal custom mold creation. This is the stage wherein you can fix everything needed.

Conclusion

Rapid tooling is one of the commonly used technologies in the manufacturing industry today. It is very useful for creating prototypes before the actual manufacturing stage. There are many benefits of rapid tooling and most importantly it has reduced production time and cost in manufacturing. It has become possible to look at the actual product early in the production process and make all the necessary changes because of rapid tooling technology.

Rapid tooling has become very important in production or manufacturing where it has become possible to look at the actual product early in the production process and make all the necessary changes.