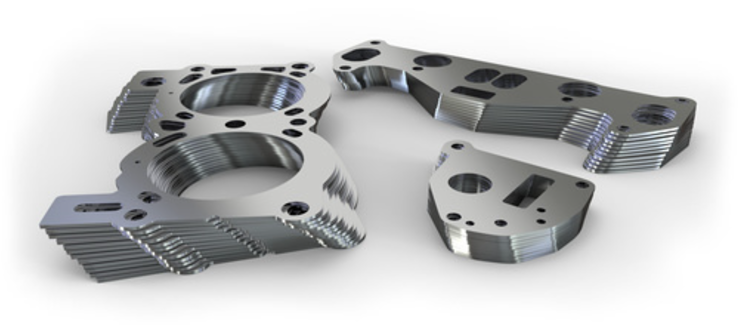

Rapid tooling can be understood as the combination of rapid prototyping techniques and conventional tooling practices to quicken the mold production. This is the process which is also in use in preparing parts from functional model like CAD data in lesser time and at very low cost.

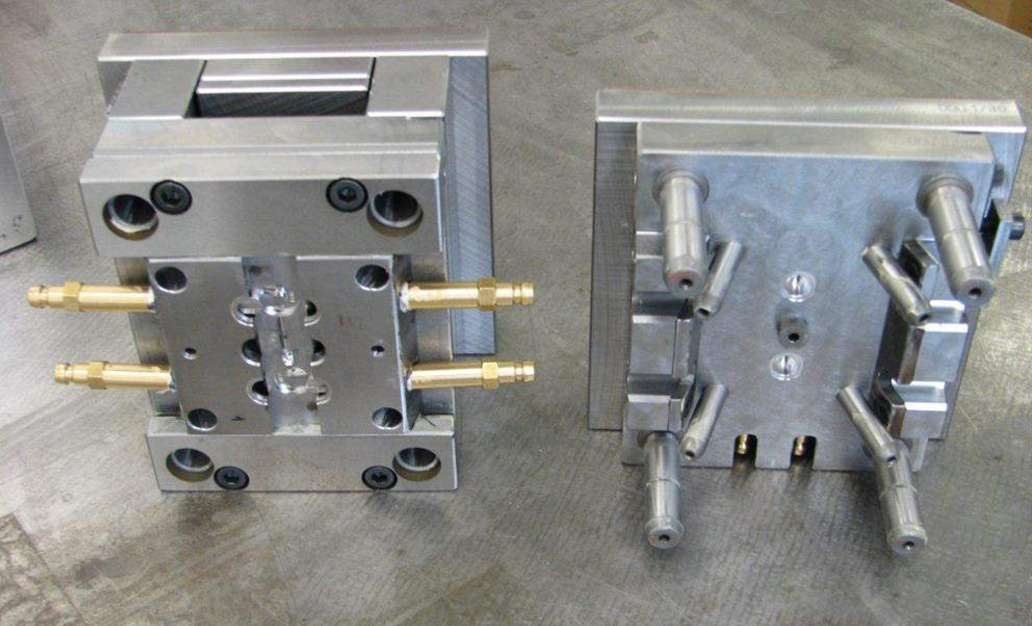

The cost for production of molds using rapid tooling is always lesser compared to traditional machining methods. So, this technology is best suited for serving the production of injection molded parts. In some cases, the rapid tooling makes use of rapid prototyping models as the pattern for production of parts. In other cases, it directly uses rapid prototyping services. In both cases it aims to fabricate tool in limited quantities as a prototype for a product.

If the volume of the production is really high then, even if the cost of production is more there is nothing to worry. But when the volume is low, then one must think about low cost productions. Since rapid tooling can result in prototypes in less time and less cost, this is best suitable for businesses where the main concern is small manufacturing quantity.

During any product development life cycle, there is a need for intermediate tooling which will produce lesser quantity of prototypes. This helps in performing the functional tests. The small volume production is later used as marketing samples. This can also be utilized for evolution purposes as well. Prototypes play a major role in production process design as well. These are the reasons because of which rapid has become very important for manufacturing industry.

There are many benefits of this rapid tooling technology. Rapid tooling results in offering lesser time to produce a prototype compared to conventional tools. Cost of tooling is really low compared to earlier technologies. But one challenge that usually faced in this case is toll life. Here one must understand that the tool life in case of rapid tooling is comparatively lesser than conventional tools. But other advantage is tolerance of the tools will be high compared to that of conventional tools.

Table of Contents

ToggleRapid tooling: Benefits

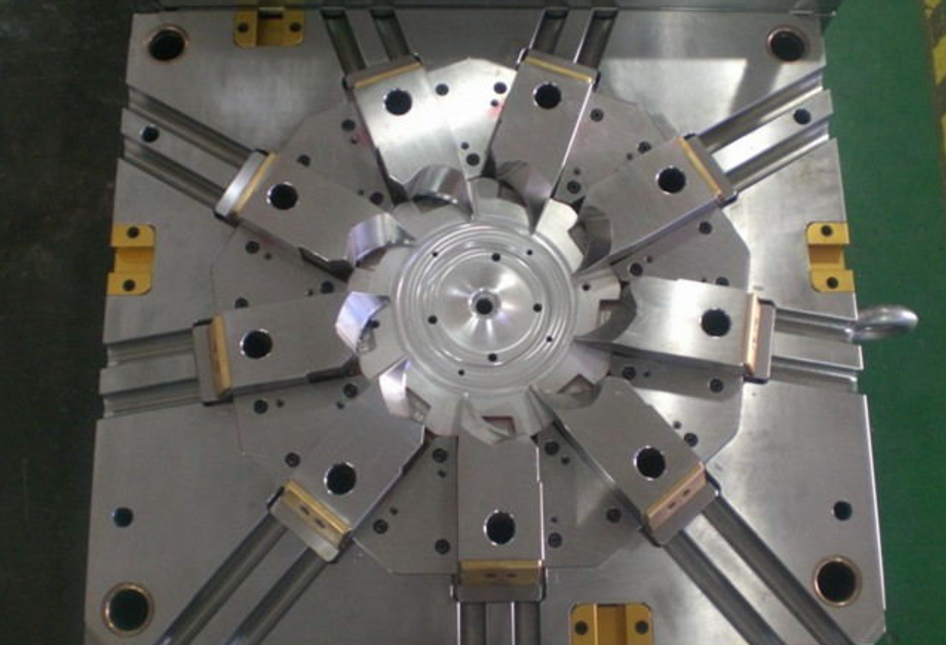

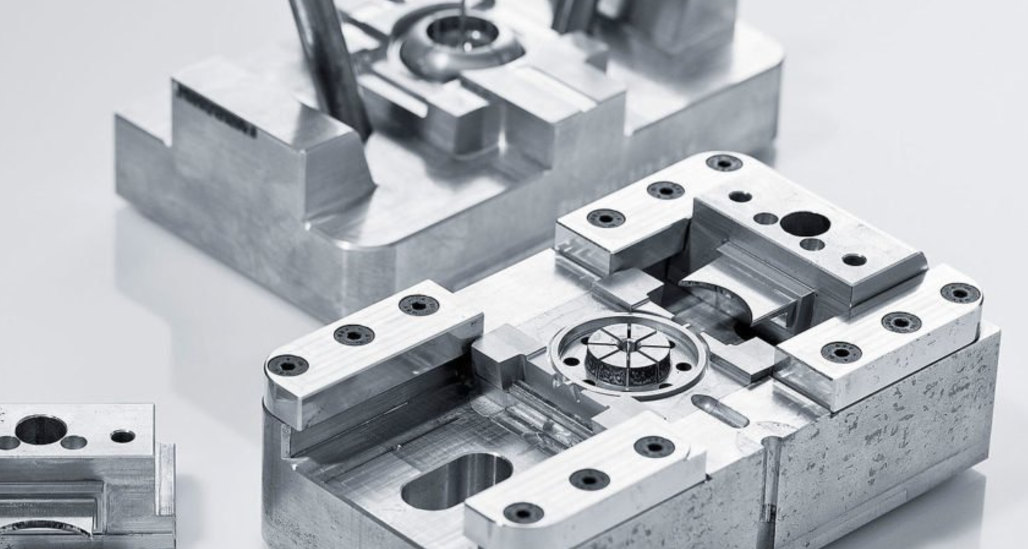

Rapid tooling is the process where building of core and cavity inserts occurs as a product of the rapid prototyping technology. There are number of advantages of this process. Some of them are,

- There will be a scheduled time decided for every product. If the manufacturer uses rapid tooling technology, then it is possible to brought the product much earlier than the time fixed

- People who are waiting for the product will get it in less time and for low cost. The cost will be less in when we compare that to the product releases after mass production

- Rapid tooling can help the production of varieties of products from larger range of materials

- Along with production of prototyping, rapid tooling can also facilitate the manufacturing of other small quantity products

- This can also be utilized in troubleshooting of the existing problems in the products.

- Today rapid tooling is in use even for creating molds which are for commercial operations. This is because the time taken to complete the process is much lesser in comparison to other manufacturing methods

There are many alternative methods but they demand more time as well as more resources. But rapid tooling has becomes the quickest process in the production of required tools. This is the reason companies opt for this since they can produce the commercial products in less time using the benefits of rapid prototyping.

Additional benefits:

There are many other benefits of rapid tooling like it is possible to achieve customization through this process. So, for personal applications, rapid tooling can provide all the necessary customization. Through this it is possible to refrain error measurements and to perform all the personal trials. In case of any issues, it is possible to fix the problem through CAD programs.

The staff here can easily decide the type of rapid tooling materials which are used to produce the product of customer demand. Especially the staffs who work on 3D printing can easily understand the requirements of the clients. There are many benefits of die casting but majority of the purchasing decision makers, engineers, and designers are still not sure about this technology. Along with this, it is most suitable for high volume production.

So, through the development of techniques in rapid tooling will end all these misconception. This makes the way for designers to grab the benefits of these technologies. So, through this advantages of die casting will reach to wider range of applications and products.

There are many technologies even in rapid tooling which can reduce the lead time. This has already reduced the lead time to as little as 7 days in few cases. The cost is also reduced to significant range through these rapid tooling technologies.

There are number of manufacturing industries which are already making use of these rapid tooling technologies. It is best suited when the aim is to produce a best prototype for a product. Since the cost and time is less compared to conventional methods, it is easy get a visible product in less time.