Troubleshooting and testing are some of the most critical stages when you are dealing with products development, most of the times the creative team behind a new design new to do multiple tests runs to approve the next stage of tooling or manufacturing. Place on top the fact that almost every product out there needs to meet the regulations and market standards where their customer base is located, and you can start to grasp why manufacturing is such a complicated process. When it’s time to deal with each stage on its own, many developers seem to think they can get a finished product by taking shortcuts on one them. That could prove to be a huge mistake.

A production run and prototype tooling are two very different stages of any project centered on product development, and they complement each other. But the work done on each one of them must be handled separately without parallels. These are the reasons why, logistically speaking, one must go before the other:

Table of Contents

Toggle· Prototype Tooling Goes First

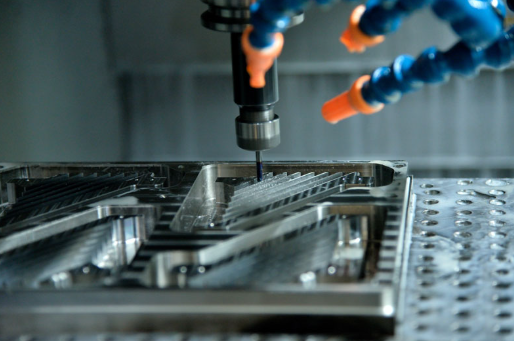

There is such a vast number of decisions that must be made at this stage that is impossible to list them all in this basic guide, suffice to say that all the critical elements of the prototype are created here. Using CAD software or any other 3D modeling design program a developer can work out even the tiniest details of the product before building a prototype using 3D sculpting.

· You can program your Schedule Accordingly

In the past, there was so much time lost in revisions that managing realistic schedules that didn’t take months or years of time was out of the question. Modern prototype tooling took long development schedules out of the equation in a single, swift strike. The number of components available to craft a prototype and removing the human factor out of the sculpting process with technology has made the creation of prototypes so manageable that production can be scheduled within 2 or 3 months in advance after making all the necessary revisions.

· Production is About Quantity

Once the development phase is done for, it’s time to handle the logistics of a production run. Quantity plays a significant role here since even small companies have minimum requirements when it comes to taking orders from developers. Although many manufacturing companies can handle low numbers these days, the engineering required to manage the production settings of any project must be worked out and programmed, and that takes time as well.

· The Choice of Materials Determines the Production Run

After having your prototype tooling lock and loaded you need to work on realistic expectations. Rushing the manufacturing process always yields poor results. Even big corporations have learned that the hard way. Working with light metals, it’s not the same as working with plastics, resins or anything else for that matter. Tooling does have a limited production run, so developers need to make sure that the company handling the molds let them know how much time they have to place another order. Take a moment to listen to the team tasked with the product development they will always make the best recommendations in your best interests.