We all know that Apple is one of the famous and reputed company in the market and each and every product released by apple company gets a pleasant welcome in the market. As same like all other apple products apple’s new macbook and Mackbook pro get high value between the people.

This is because of the special features present in the product and one of its remarkable feature is its precision enclosures milled from an extruded block of aluminum material which permitting them to get even thinner body whereas retaining rigid durability to the product.

Due to this feature apple macbook has a stronger, cleaner and more polished design than all other products. In this article we are going to Know more about the CNC machining process for macbook Pro case

When this product was released in the market, one of its creator said to the press as apple company has invented a whole new way of building notebooks from a single block of aluminium material and apple company’s senior vice president of industrial design said that this is traditional notebooks which are made from multiple parts together.

And with the new macbook, the company replaced all small parts with a just one part as unibody product. As in simple definition, the macbook’s unibody enclosure is made from a single block of aluminum and it makes the new macbook fundamentally thinner, stronger and more robust with a fit and finish which is never even dreamed before on any other products.

CNC unibody fabrication:

The previous models macbook pro uses a thin and bowl-shaped shell which has an internal skeleton to hold the internal parts of the body together. The top bezel lays on the top and it is screwed in a place on the sides and back edge of the product.

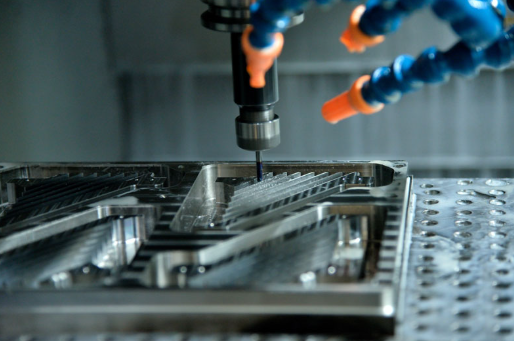

All these pieces permit for some tolerance that needed for plastic gaskets to fit the components together snugly. The new 15” macbook Pro is starts with an extruded block of aluminum which is carved out using CNC mechanism.

The CNC is approved as computer numerical control which is build in machines in a process used by the aerospace industry to build mission-critical and high precision components. Let us see the steps involved in processing the CNC machine with macbook.

Step 1:

The process starts with a raw aluminum which is selected for its favorable strength to weight ratio and the flexibility it offers in processing and finishing.

Step 2:

Now the Extruded aluminum sheets are cut into blocks that undergo 13 separate milling operations.

Step 3:

The Apple uses CNC to precision cut keyboard holes from the face of the slab, mill out the thumb scoop that provides enough of a recession to open the display lid comfortably without putting too much pressure on the lid, machine out complex patterns from the inside and perforate the speaker grill holes using lasers.

Step 4:

A portion of the front edge is milled thin enough that a laser can be used to micro-perforate the metal to allow light from the sleep indicator LED to pass through the metal. When the sleep indicator is off, the metal appears to be solid. Apple has already used this process on the macbook Air and the Bluetooth Keyboard that shipped last fall alongside the aluminum imac.

Step 5:

Once the inside is precision cut leaving a design that is, as i’ve observed, in many ways more beautiful internally than externally the edges are rounded and polished.

That’s it the macbook is ready with a CNC machine.