A lot of developers commission full projects to plastic injection molding manufacturer overseas. When you hand over the development of your project, the most natural expectation is to receive a part that is fully functional in every single term. After all, we are looking to release a successful product that reports earnings and profits even after you are done with it. Since you are aiming high, you probably need to follow a guideline to make things work on your terms. The following is a list of basic rules you need to consider when you commission a project to a third party. Take them as they come and you have a great chance of being successful.

Table of Contents

ToggleGet the Legal Department on Your Side

If you don’t know how piracy affects every single legitimate business in the world, you probably are not paying attention to the metrics related to your business. When you develop a part and commission manufacturing to a third party, it can be really easy to lose your design to piracy even if the developing company secures your design with safety protocols.

There are also a lot of liability concerns driving design and production. Since you probably don’t want to recall your product because of a fault in the design, the best you can do is reduce the risk of exposure on your company’s end by ensuring the protection of users with solid terms of use. The best people to handle both cases are a solid legal department that knows their ways on the law on every ground you may need.

Take a minute to remember how big companies such as Samsung and Apple have been able to handle recalling their products when they fail or are shipped with a faulty design. Companies usually absorb the blunt force of any lawsuit that might come their way, but they are generally covered in legal terms because the terms of use place a great deal of responsibility on the user just for buying the product. The same happens with certain medical supplies or any product that includes injection molding parts.

Make Sure your Product is Built to Last

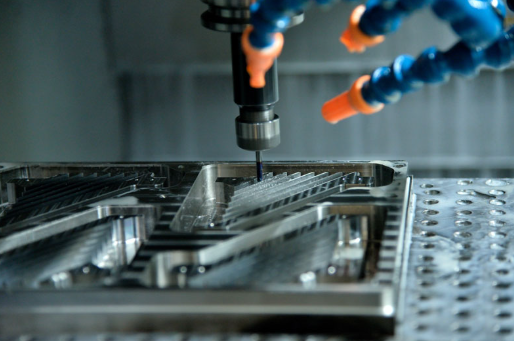

Every project that aims to use a plastic injection molding manufacturer has to go through a design stage using CAD models. Before doing that you need to take into account several features regarding the built of your product, especially those regarding how long it will last as well as how sturdy it will be.

Most of these factors must be included in the instructions of use provided with your product, even if the user doesn’t take the time to read it, you should make clear in your terms of use the acceptance of these conditions once the user opens the package. You should also make sure to cover the grounds regarding things like:

- Environmental care or all the aspect related to the proper care of your product and the right environmental conditions to keep it working, as well as the ones that affect it.

- The lifespan of the product and everything related to how long the product can last given extensive use.

- The type of resin used to cast out the product. Every plastic injection molding manufacturer works with an extensive catalog of resins and plastics. You need to make sure they are working with the ones that will make your project last following your specifications.

- Limitations of the manufacturer’s hardware. Simply put: it the plastic injection molding manufacturer is not capable of delivering the product as you request it, maybe there are not suited to handle the task of creating it in the first place. Plastic injection model projects use a lot of thermoplastic resins, and the manufacturer must be able to control the environment where the project is developed to offer the expected quality.

After you have a sense of control on these features, you can begin to pour CAD data to bring a prototype. The preferred tool to have a working prototype quick is a 3D printing technology, and most modern engineers are already familiar with this environment to make any change if needed.

Design a Great Project and Reap your Success

After planning your concept and creating your project. It’s time to bring it to life. There are still a lot of challenges to overcome. The plastic injection molding manufacturer you choose to work with will have to cast the metal cast to create your product, and that needs quite a few revisions and tests to make sure it works properly. If possible try to hand out the full extension of the project to a single developer. It may be more costly, but it will also make for a much better fit since they will not be able to place blame on other stages of development if something comes out wrong.