Most of the time a brand new entrepreneur will come seeking rapid prototyping services without the slightest idea of what is needed to handle their projects. Services providers weren’t exactly forthcoming in the past with this kind of assistance, but these days is pretty much standard for many of these companies to make a full case study on each project and offer as many options as they can to developers to get their products done.

3D printing and rapid prototyping are one of the many solutions they can provide when time and performance are an issue, it’s important to get a sit-down with the client and get the full spectrum of their project on their end. Sometimes the manufacturer can accommodate their requests. More often the project will have to go through revisions.

Table of Contents

ToggleWhat Lurks Behind Every Manufacturing Project?

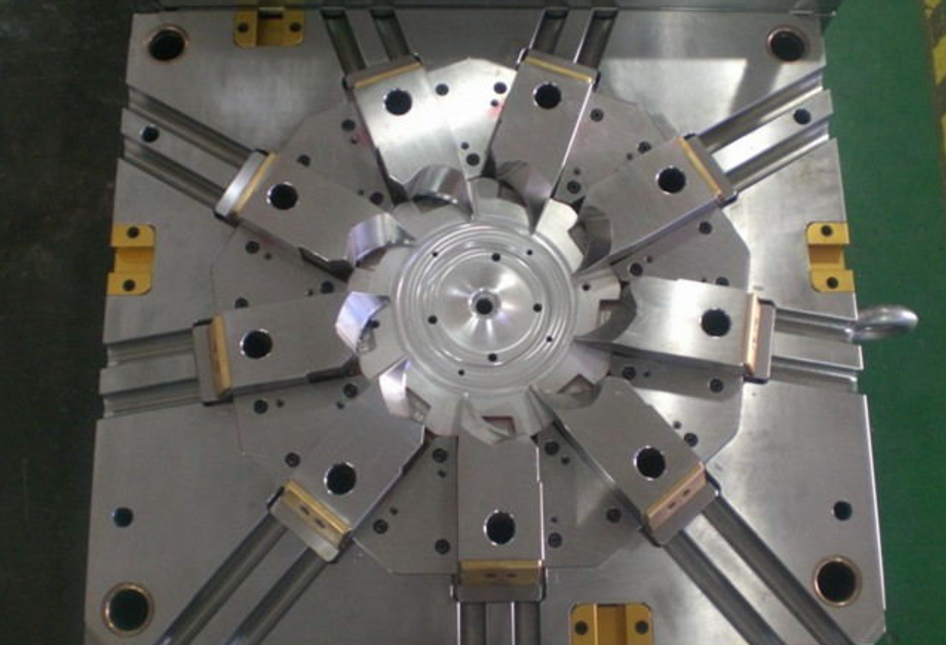

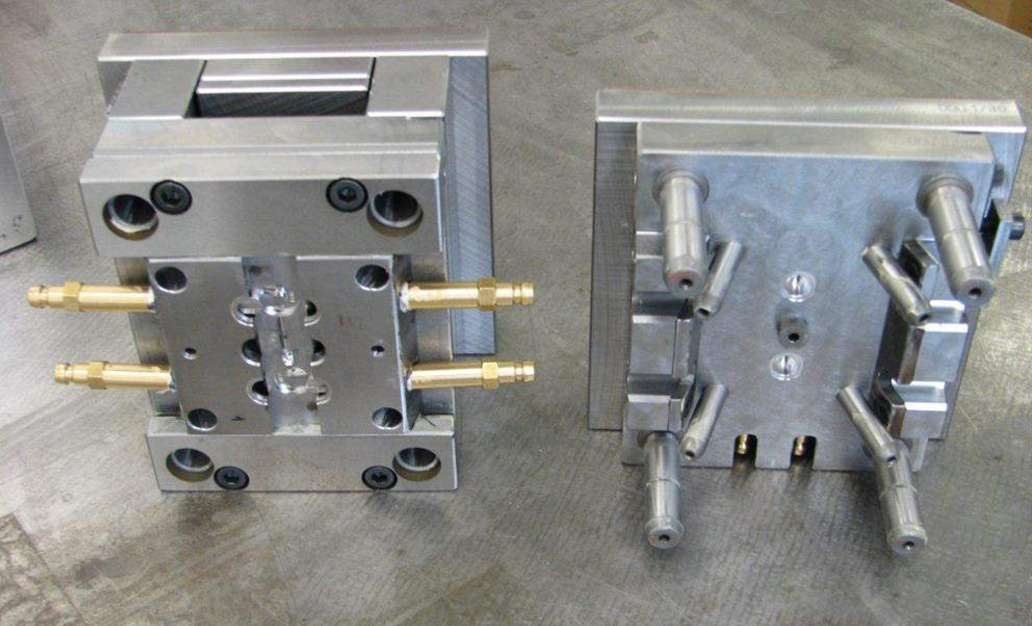

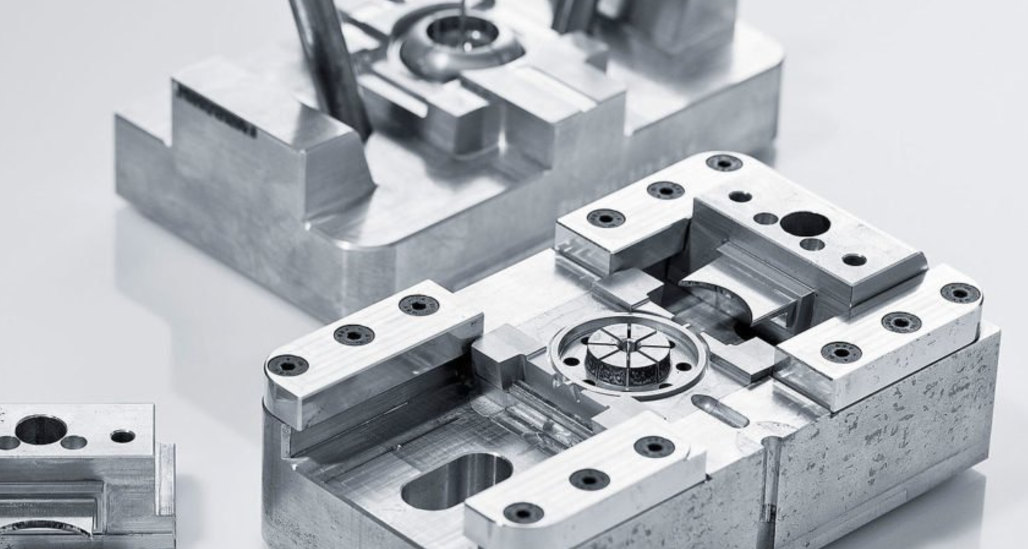

The hard facts are that most of the time the most powerful development techniques are not required to handle specific projects due to their size and the number of parts that are asked in the order. 3D printing is not a magical solution and rapid prototyping services most of the time can offer other alternatives such as the creation of molds and casting for extended runs of the parts you need.

It certainly boils down to the complexity of the project as well as the size of the order. If you need 1,000 units of a product, you can have it made using 3D printers, but if you need something that has to fulfill specific quality-based specs on a low run, the cost will be vastly reduced since you won’t have to create a mold. Anything that goes over five figures in units will need the additional expense.

Dealing with the Reality of Logistics

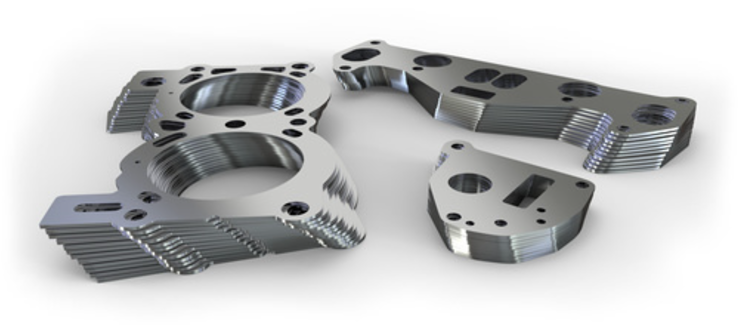

As you get more involved in your project, you will learn about how the ever-changing logistics can make or break your project. Your disposition to adapt and overcome these obstacles will determine your success. 3D printing can undoubtedly help you drive production costs down and get a product that is tailored to your specifications. The performance of your product, however, it’s an entirely different matter.

The engineering process on the planning stages should keep everything clear for you, but after doing a test run and creating your first prototype, you might notice things that need to be changed. This is a common occurrence when you are dealing with parts that are created using plastic materials such as silicone, plaster or more rigid resins. Retooling could be necessary. The outcome of the revisions will determine how worthwhile the project for your manufacturer is.

While most rapid prototyping services can be pretty accommodating, some will inevitably tell you that changes are needed. It’s up to you to go for it or shop around your idea to get other alternatives. Remember that manufacturing is a science-based process, but it’s also very flexible. A sizeable budget can certainly help, but a small entrepreneur might not have that luxury.