There are more than 85,000 of materials available for plastic injection molding, and these are classified into categories: thermoplastics and thermosets. Selecting the correct material is important in plastic injection molding to get the best outcomes. For a successful product, the material selection is a step that should not be neglected.

The reason for its importance is simple. It is a factor in on every process of product development. Here are the processes where material selection matters in plastic injection molding.

Table of Contents

ToggleEnd Product

It is easy to see why the material affects the product. If you choose the wrong material, your product will not do the function it is made for and perform what is required from it. It is that simple. If you use a flexible resin for a product that requires rigidity, then your product fails. Medical equipment and food handling items will be hazardous if you choose a non-medical or non-food grade raw material.

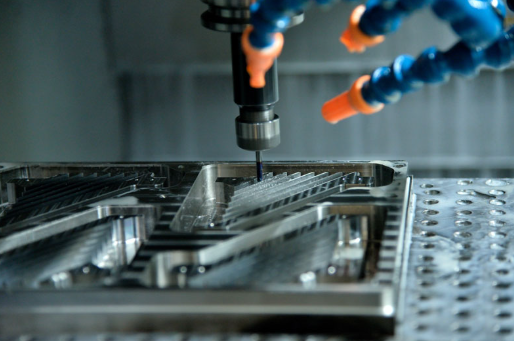

Plastic Injection Molding Process

Different materials will have different properties that affect the manufacturing progression. Material properties like viscosity, cooling point, and melting point are an important factor to consider. The highly recommended material should have all the desired properties to be able to handle complex molds. However, some products may require different melting and cooling points to help obviate problems like voids and sink on the finished product.

Budget

To select the best material for your project, you must be able to know many points. You should know the complexities and the design of your mold to grasp the plastic injection molding process. You should also have the full information on the finished product to be able to arrive at the right material with all the qualities that you need. This way you will have the finished product at the lowest expense possible. You do not have to pay for a high-grade material that has the properties and features that you will not need.

Thermoset vs. Thermoplastic

Another important information about the material that you should know is the difference between thermoset and thermoplastic.

A thermoplastic is a type of polymer that becomes malleable when they are heated to an exact temperature. This material is very easy to mold at a specific temperature and will harden into solid when they are cooled. Another property of this material is they are recyclable, meaning, they can be reheated, reformed and reclaimed repeatedly.

Thermosets, on the other hand, are composed of polymers that are cross-linked together during the curing process making them impossible to re-melt when heat is applied. One of the applications of thermoset plastics is in sealed products where resistance and structural integrity is needed.

Conclusion

Every material in plastic injection molding has its own properties. This is why it is important to know the defining characteristics of each of them before selecting the right one for the plastic injection molding process. In some process, if the material falls short of certain properties, an additive or filler is used to get the correct material properties.

Narrowing down your list by using the defining characteristic you need will help you choose the best material to improve the form and purpose of your product.