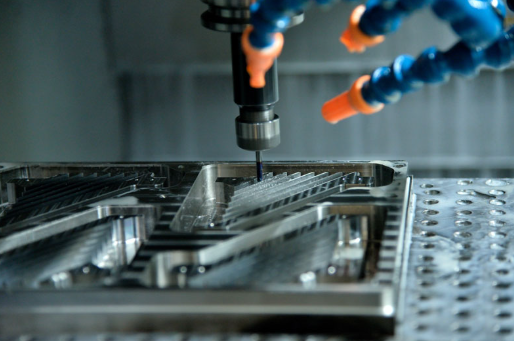

Fixture plates are also known as tooling plates or module fixture plates. They are built using aluminum, and they are used to mount parts efficiently while saving time in the manufacturing process. They are usually low-cost, and their disposability means they are frequently crafted to handle custom-made jobs using CNC machining. A Fixture plate has a lot of threaded holes that are protected against any leftover chipping by a set of screws that can be removed to use the punching holes as you deem fit. Sometimes these come with a series of engraved letters and numbers to create coordination systems that allow easy identification of the parts you are building if they have multiple components.

Table of Contents

ToggleWhy Should We Use a Fixture Plate?

Many people create fixtures on the go using basic t-slot tooling, but even something as useful as those long-standing instruments have their limits. Fixture plates can be positioned anywhere to do specialized work. They are considered a precision tool among CNC machining services since g-code programs take full advantage of it. Unlike the work that is done using t-slots where a fixture must be installed and measured manually, with fixture plates the job can be carried out after being programmed just once, as long as you are working with slabs of raw materials with standard measurements. As you can expect this save a lot of time and all your fixtures will be done in the proportion, location, and orientation with little to no mistakes.

What Issues Are Solved by Using Fixture Plates?

If there is one task that is always hard to handle using t-slot tooling are vises. Most of the time the job of handling vises need for parallel chops on the X-axis mark path of the CNC machine. Technicians lose a lot of time setting up the vises to be aligned with the marked trail that must be traced by the device. By using a fixture plate, bases need to be installed, and all the ramming process can simply be avoided. This feature has turned a lot of small workshops into operations able to offer high mix low volume services, meaning that they can deliver a lot of different parts from a single task in less time than their competitors. Using fixture plates, it’s also a way to get a clean finish on the part you are working on with proper use of cooling and much less chipping.

So Fixture Plates are a Problem Solver?

It certainly seems that way, especially when you factor in the time your company will save by having all CNC projects handling tasks in lesser times. As you can expect, this will give your operation an opening to take on more projects and increase your profits. Fixture plates are a sound investment, one that you may need to undertake one time too many. But once you can understand the mechanics behind it will prove to be beneficial for you and your clients as long as you keep your CNC machining working correctly.

*Pictures from others websites, please let us know if you own the copyright and want to take off the site.