- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

3D printing is an additive manufacturing process where a three-dimensional object is crafted layer by layer, following a digital model.

Modern 3D printers can produce complex geometries, employ a range of material, and are utilized in industries ranging from fashion to aerospace.

3D printing from APT creates a platform where design intricacies and customization are not bound by the same limitations as conventional methods.

Designers and engineers can now iterate prototypes within a fraction of the time traditional methods require via 3D printing.

3D Printing, being an additive manufacturing process, uses materials more efficiently, layering them precisely where needed and minimizing waste.

3D Printing has the capability to produce parts with complex internal structures, such as honeycombs or lattices, which retain strength while shedding unnecessary weight.

The possibilities for customization are virtually endless, enabling artists, designers, and inventors to explore realms previously deemed unreachable.

3D printing offers a pathway to cost savings particularly noticeable in short-run productions and prototypes with no initial expense of setup of production lines.

We ensure that our customer have the right item in the right quantity and at the right time to support them quickly respond to market changes.

3D printing from APT creates a platform where design intricacies and customization are not bound by the same limitations as conventional methods.

Designers and engineers can now iterate prototypes within a fraction of the time traditional methods require via 3D printing.

3D Printing, being an additive manufacturing process, uses materials more efficiently, layering them precisely where needed and minimizing waste.

3D Printing has the capability to produce parts with complex internal structures, such as honeycombs or lattices, which retain strength while shedding unnecessary weight.

The possibilities for customization are virtually endless, enabling artists, designers, and inventors to explore realms previously deemed unreachable.

3D printing offers a pathway to cost savings particularly noticeable in short-run productions and prototypes with no initial expense of setup of production lines.

We ensure that our customer have the right item in the right quantity and at the right time to support them quickly respond to market changes.

As it evolves, 3D printing technology is destined to transform almost every major industry.

Automotive

3D printing enables new designs for more efficient solutions, pushing customization to the limit of what is possible.

Consumer Products

3D printing brings a new dimension of personalization and creativity to the table. Designers now have the freedom to create intricate patterns and designs that were previously unthinkable.

Education

3D printing enables students to materialize their ideas in a fast and affordable way. Printed prototypes are very common in the arts, animation and fashion studies, etc.

APT offers versatile material choices, including high-strength resins like ABS, PC, Nylon, etc., grants designers the freedom to engineer products that precisely meet specific strength and weight criteria.

+86 18814246095

Here are the answers to the frequently asked questions. Any other questions, please feel free to contact us at enquiry@apt-mold.com.

3D printing is an additive manufacturing process, making objects from 3D CAD data. Typically, 3D printing is a layer-by-layer process where part geometries are “grown,” fusing with the previous layer. 3D printing processes can build objects in plastics, photopolymers, metal and other materials.

SLS (selective laser sintering) is a 3D printing technique that uses a laser to fuse together small particles of plastic into a solid object. SLA (stereolithography) uses an ultraviolet (UV) laser to cure (harden) liquid photosensitive resin into the desired shape.

The parts produced via SLS are tougher than those of SLA, so they’re more often used as functional parts. While SLA systems provide greater resolution than their SLS counterparts, so SLA produces parts with better surface finishes than SLS.

Though all file types are ultimately converted to STL (.stl) before printing, the recommended file type to upload is STEP (.stp/.step) and IGES (.igs/.iges) files.

If you do not know anyone who knows how to handle a 3D modeling software (CAD software), you may look up your local yellow page to find a design service bureau and have them design a specific object for you.

3D printing accelerates the process by reducing the time and cost associated with prototyping and refining the design. Highly realistic prototypes printed look like the final product, cultivating faster and better decisions.

Justo ornare ad elementum aenean lorem penatibus amet consectetuer blandit natoque. Vestibulum tellus felis egestas ullamcorper parturient molestie aenean condimentum.

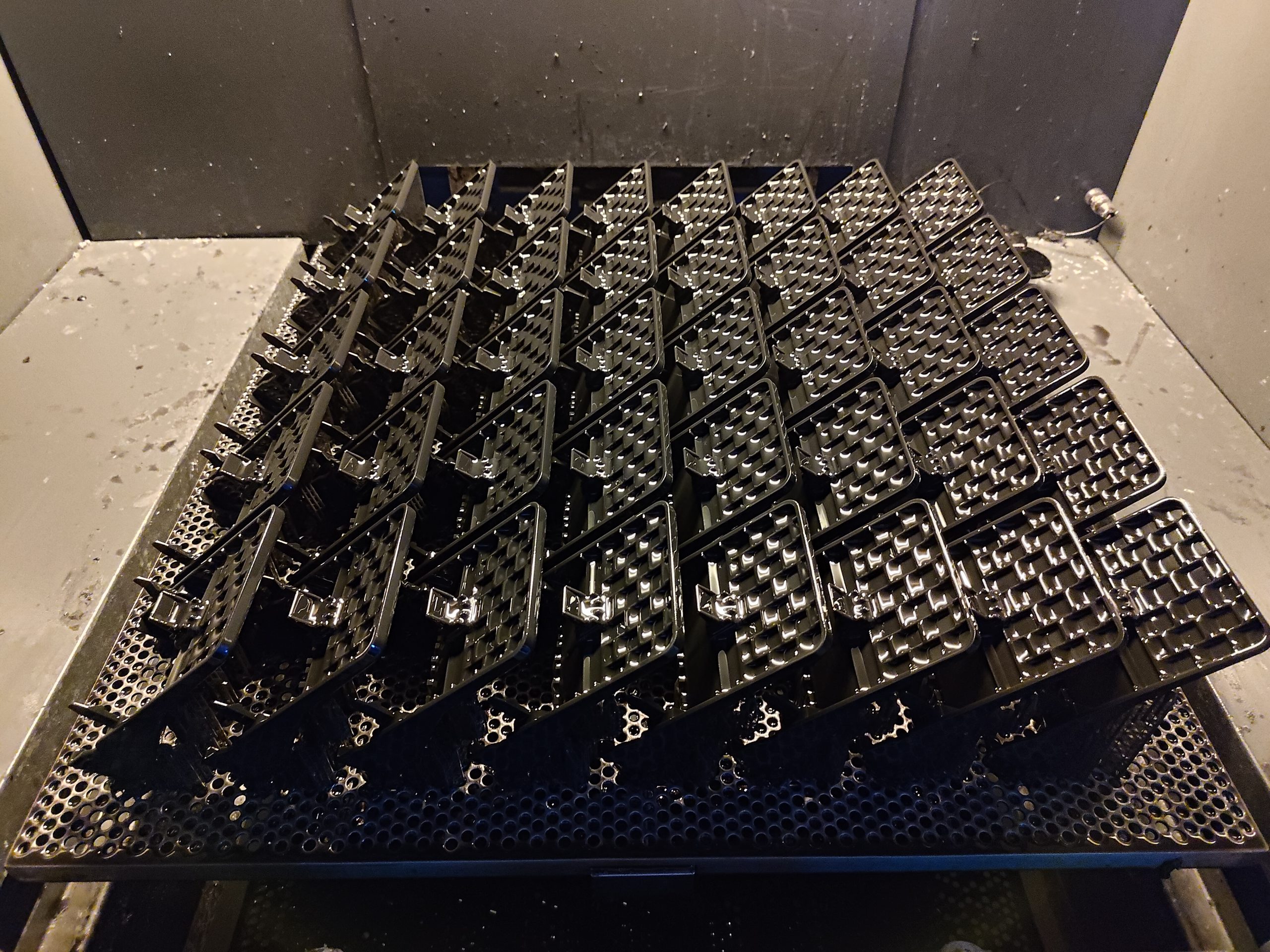

Case1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

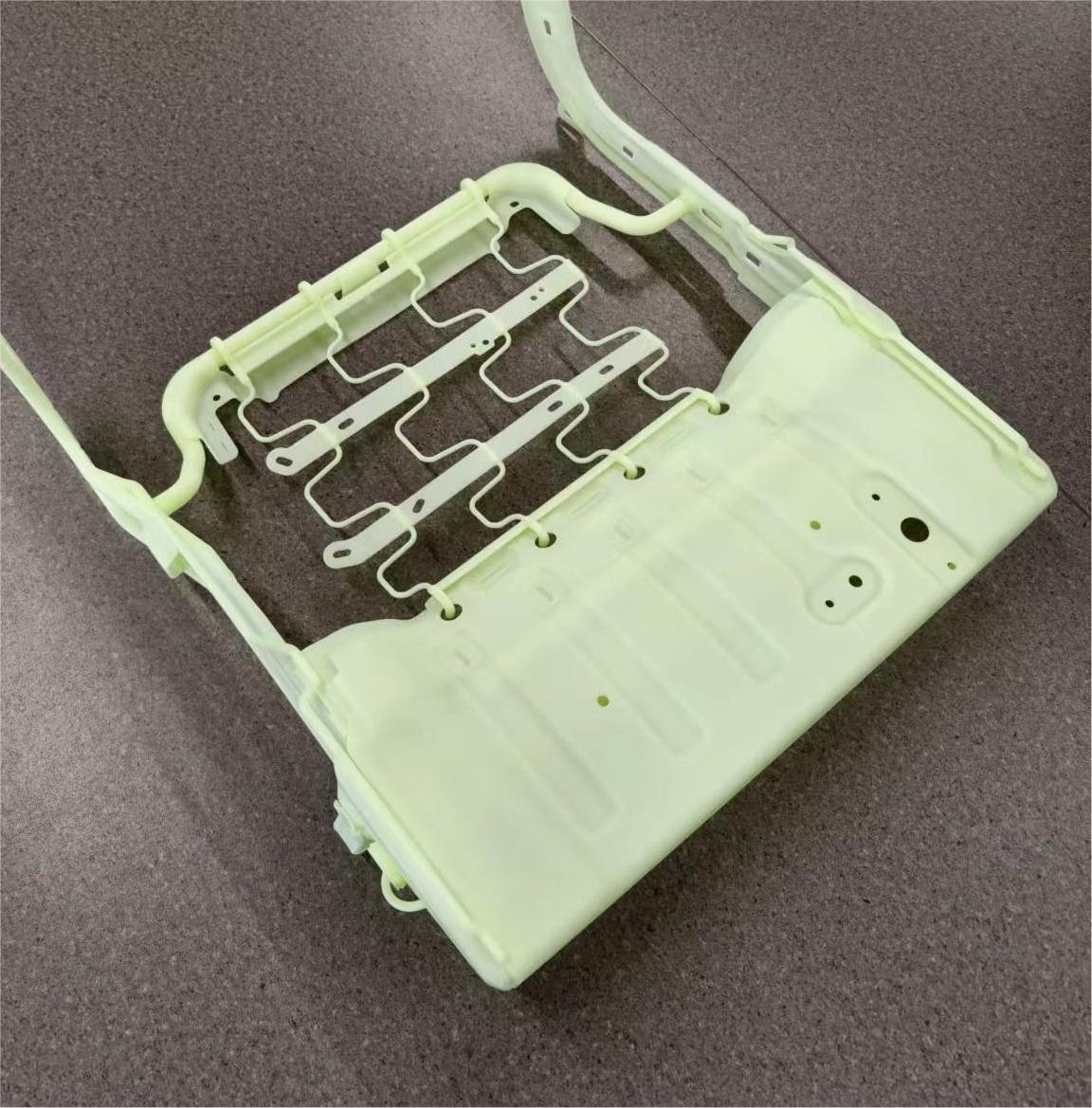

Case2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

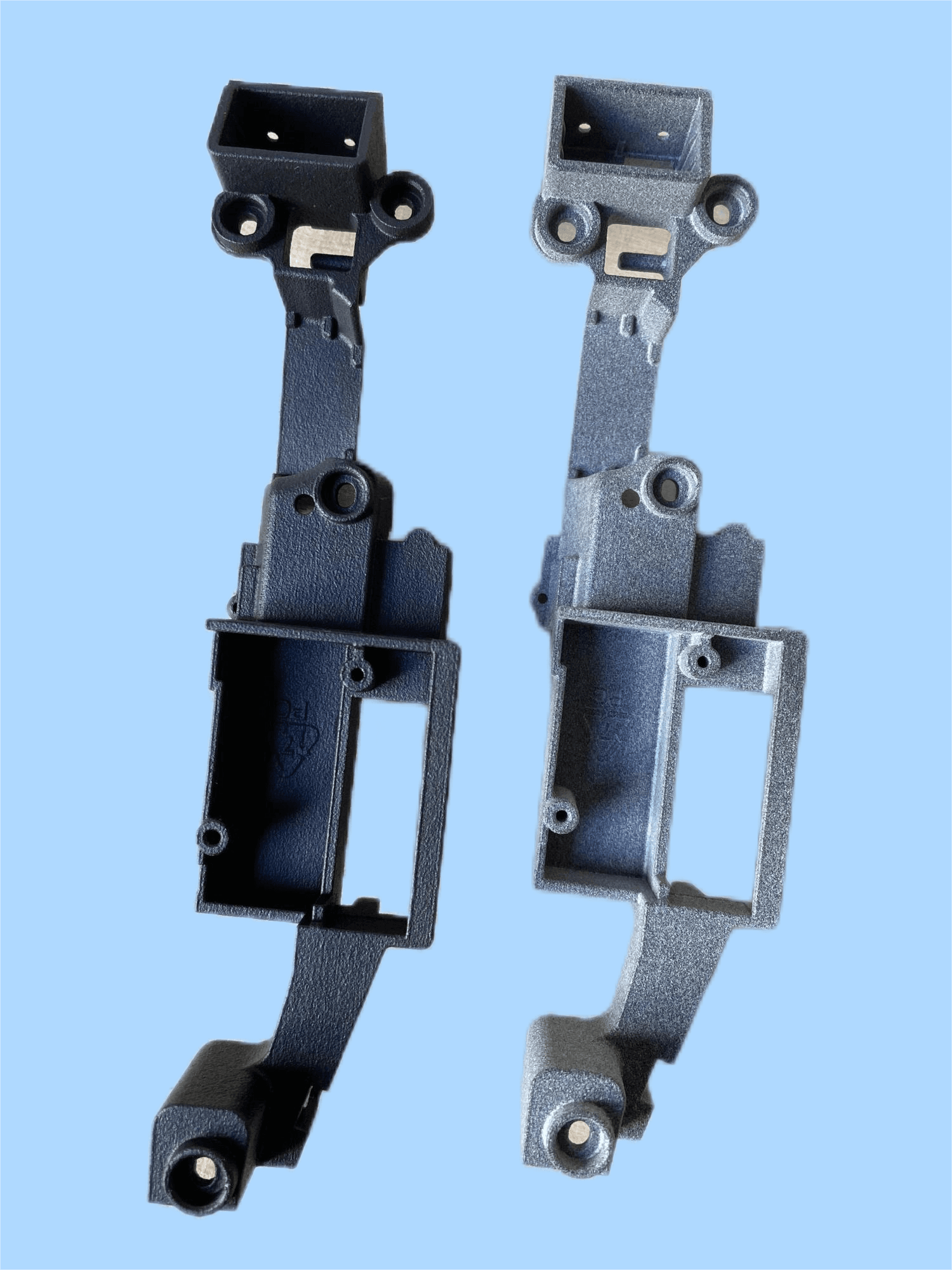

Case3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.