- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

By analysis of quality costs, and using techniques for defect prevention rather than detection, we aim to establish quality processes targeted specifically at defect reduction in variability of the process. Our goal is to minimize your risk and achieve outstanding consistency in product manufacture via the following review and inspection actions:

APT relies on precise inspection equipments to detect defects in increasingly sophisticated components, to document and offer peace of mind throughout the manufacture process that we can meet and maintain the high demands of the customers.

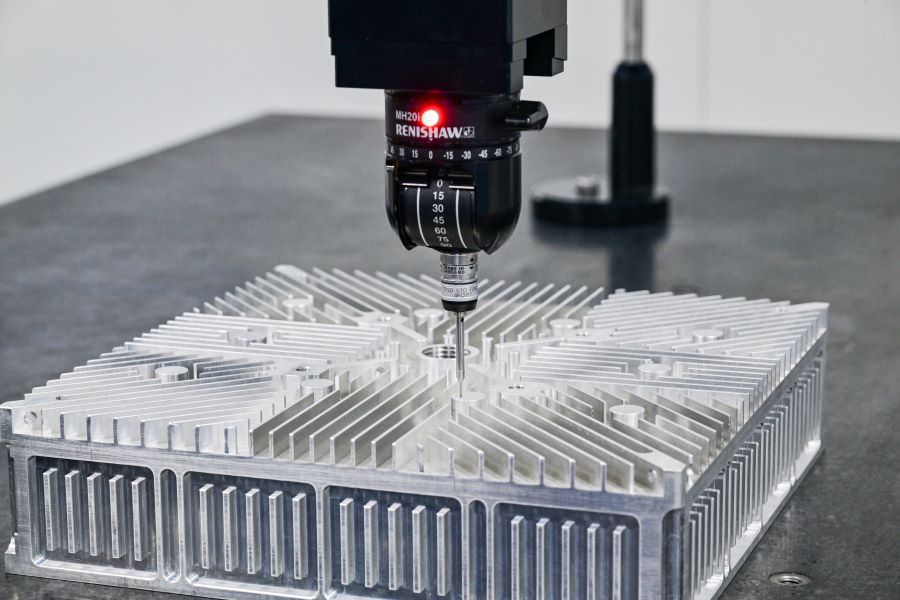

Coordinate Measuring Machines (CMM)

Coordinate measuring machine provides unparalleled precision and accuracy in measuring the dimensions and geometrical features of the manufactured components.

Our team of experts customize CMM inspection plans for a variety of components to validate exact specifications required for optimal performance.

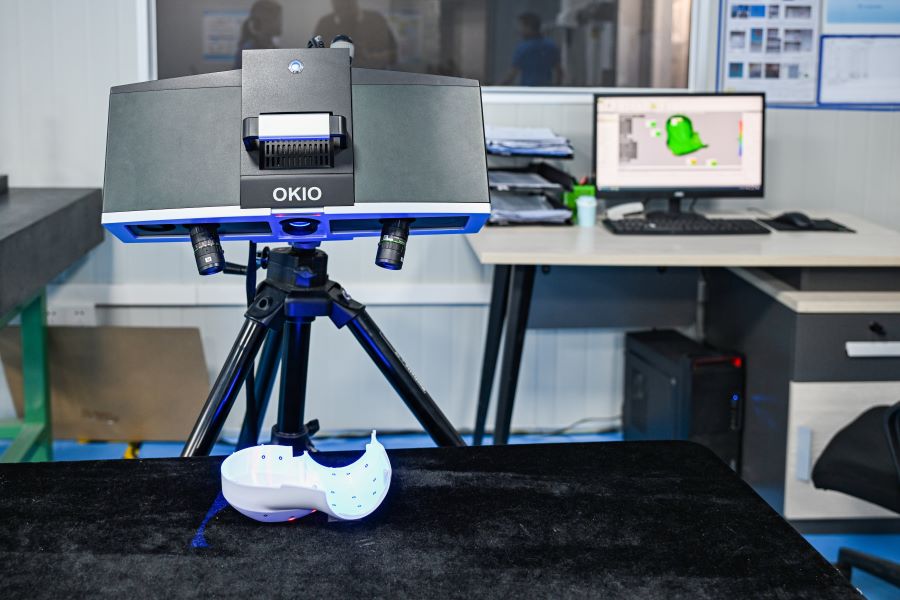

3D Scanner

The metrology-grade 3D scanner is regulated by a set standard for inspection tools ensuring that the data extracted by the scanner is accurate and highly repeatable, make it a reliable tool for quality assurance.

Using a 3D scanner and the included software for product verification is also a fast way to compare physical objects to the original CAD drawings, generating a continuous confirmation that the products or parts are within tolerances.

Non-Contact Image Measuring Machine

The non-contact optical measuring system uses image processing technology to perform automatic measurements that are both fast and highly accurate. These machines use high pixel resolution cameras to enable the observation of color images and to capture high quality of view. Meanwhile, the evolution of the associated software has made it possible to perform varied edge detections and to support complicated calculations with advance quality performance.

Spectrometer

The spectrometer is an analytic device that we use to verify the color of your parts. It measures color by shining a beam of light and capturing the amount of light that reflects back or transmits through to quantify color precisely. Spectrometers can provide color data for just about any sample, including plastics, paper, metal, fabric, and painted samples, etc.

Glossmeter

The glossmeter is capable of high precision and instantaneous measurement. It is used to measure the specular reflection (gloss) of a surface. Gloss is determined by projecting a beam of light at a fixed intensity and angle onto a surface and measuring the amount of reflected light at an equal but opposite angle. Different surfaces require different reflective angles.

Here are the answers to the frequently asked questions. Any other questions, please feel free to contact us at enquiry@apt-mold.com.

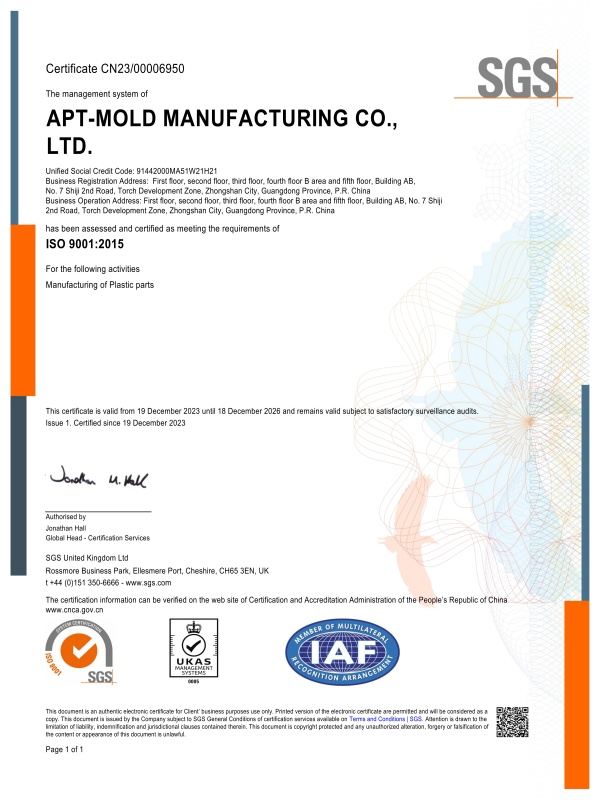

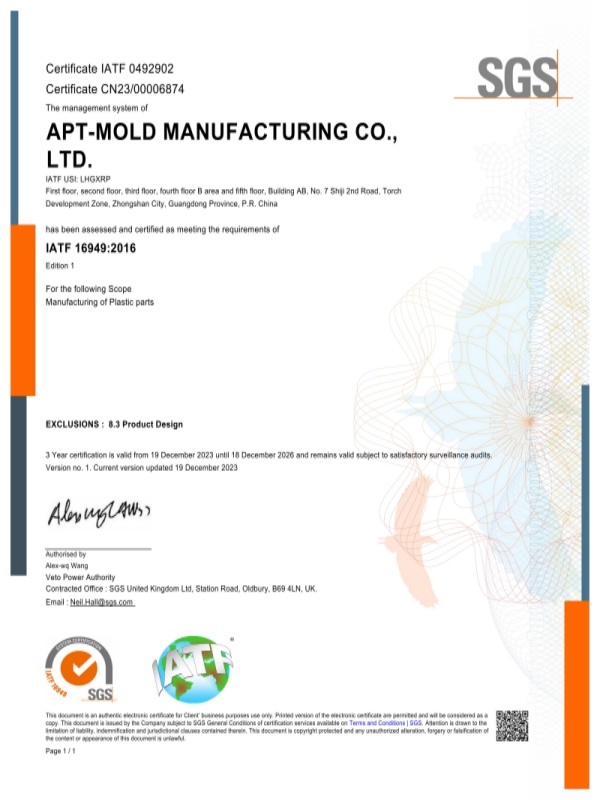

By adopting ISO9001, IATF 16949 and implementing a manufacturing ERP with built-in quality control functionalities, APT is able to focus on ensuring the fabricated parts meet set requirements and customer expectation. Through years of continuous improvement, APT has established standardized processes, regular employee training, and consistent monitoring of operations to ensure products consistently meet quality standards. Quality team at APT performs inspections at every step of the product manufacturing journey, from incoming material verification, first article inspection, in-process and final inspection. You will receive complete digital files and Certificates of Compliance so as to meet your regulatory and performance goals.

Quality certifications play a vital role in enhancing product quality at APT. By obtaining ISO 9001 and IATF 16949 certifications, APT demonstrates its commitment to meeting international standards for quality management. These certifications ensures that all processes, from the procurement of raw materials to the final production, adhere to strict guidelines. As a result, products supplied by APT are consistently manufactured to meet customer expectations.

These certifications also encourage continuous improvement and innovation at APT, and instill confidence in our customers, as they can trust that the products they purchase have undergone rigorous quality control measures.