- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

We are experts at combining a wide array of manufacturing processes with a broad palette of raw materials to make finished parts and assemblies quickly and to the highest quality.

+86 18814246095

APT continuously scales its offerings, delivering an ever-expanding menu of manufacturing capabilities

Injection Molding

Injection molding involves quite a bit of precision, control, and saving costs. It is also capable of high-speed manufacturing with less waste, less danger involved, and a larger production scale.

CNC Machining

CNC machining is precise and efficient, making it perfect for creating robotic parts. It is also relatively fast, making it possible to create large numbers of parts in a short amount of time.

3D Printing

Not only does 3D printing make it possible to get more complex structures. It can also result in lower costs, higher versatility, and additional flexibility when it comes to creating customized tasks.

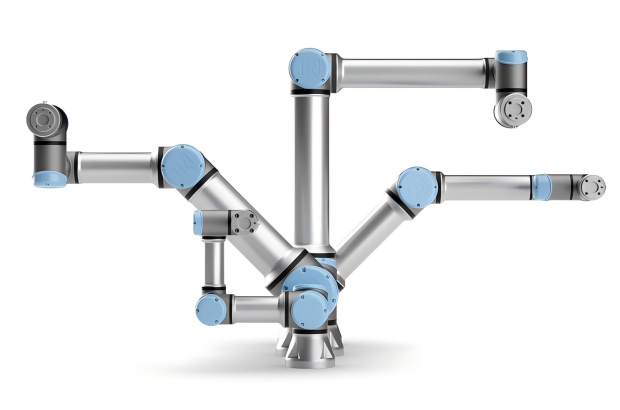

From metal to plastic, APT assists you to delve into the intriguing world of robot construction and gain a deeper understanding of the science behind these impressive creations.

Stainless steel – The high strength and toughness of stainless steel make it one of the most commonly used materials in robotics, making it a good choice for components that must survive harsh conditions and repeatable processes. Other valuable benefits include corrosion resistance and temperature resistance, and it also has the added benefit of being hardened easily and having excellent machinability. Typical robotic applications include frames, gears, end effectors, motor components etc.

Aluminum– Aluminum finds its way in robotic industry due to its incredible lightweighting, very machinable and high heat resistance capabilities which are key characteristics for robotics-related parts. Via certain post processing, anodizing for instance, aluminum can obtain significant protection against corrosion. It can also have great surface finishes that can work well for a component’s cosmetic appearance and produce low-friction parts that may be required for sliding tasks. Common usage of aluminum in robotic products include frames, customized components such as enclosures, wheels, bearings, heat sink, heat exchanges etc.

Polyoxymethylene (POM) – POM, or acetal, also referred to by the brand name Delrin, is a frequently chosen plastic material. It is extremely chemically inert, ductile and strong. Acetal has the added bonus of boasting excellent dimensional stability, low coefficient of friction and resistance to abrasion, making it commonly used in low-pressure bearings and sliding parts, etc.

Elastomeric Materials – Elastomers are employed in robots to create friction on grippers or traction on the ground. To reduce impact pressures and prevent damage to and by parts that contact the environment, they are employed as soft contacts. For strong (and damage-free) interaction with objects, they provide passive compliance in joints and manipulators. And when it’s necessary to keep liquids or dust inside or outside, elastomers are used as seals.

Simply click on the Request A Quote button and follow the instructions.

You will usually receive our quotation within 24 hours.

Place an order. We can help you easily handle all the requirements.

We start the job and deliver the parts to you on schedule, just as we promised.

Upload CAD files and submit the important details about your project.

Get quote with DFM analysis within 1 day.

Confirm Quote and Manufacturing Begins.

Qualified parts are delivered straight to your doorstep.