- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

APT can quickly, consistently and cost-effectively provide prototypes and low-volume production for the medical industry, to support our customer’s design iteration and validation efficiently.

+86 18814246095

APT continuously scales its offerings, delivering an ever-expanding menu of manufacturing capabilities

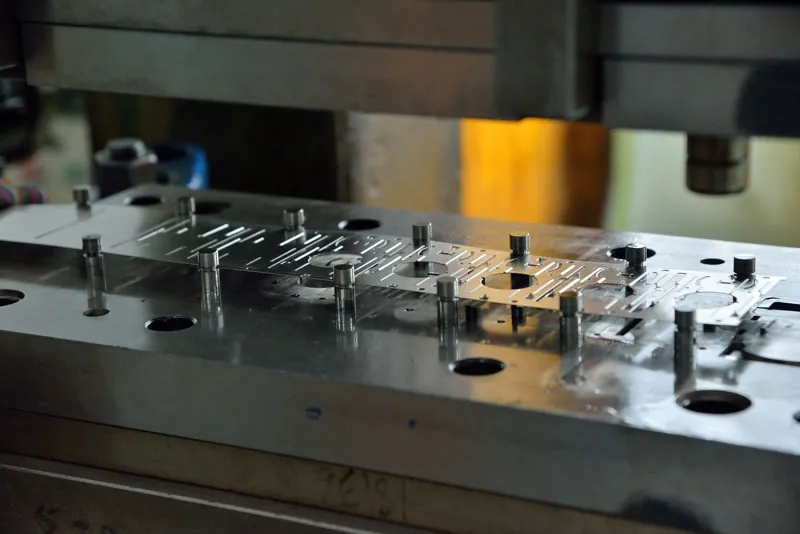

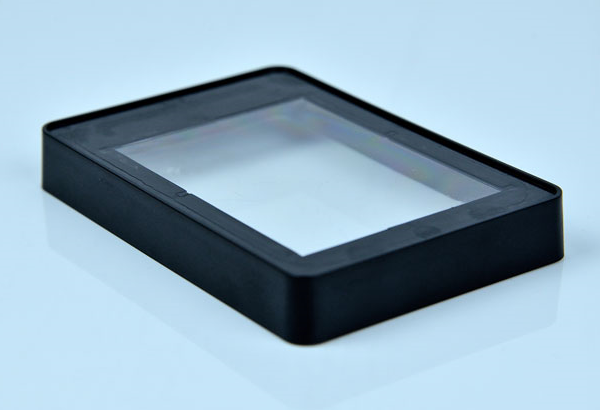

Injection Molding

Injection molding offers solutions with unparallel efficiency and cost-effectiveness for consumer goods that meet high-quality standards while optimizing production timelines.

CNC Machining

Technology-enabled CNC machining processes can accelerate manufacturing cycles, lower development costs, and help support product customization that consumers now demand.

Vacuum Casting

From show-room quality display models to end-use products, vacuum casting accelerates product development and market introduction.

Sheet Metal

The durability and versatility of sheet metal make it a common and critical technique widely used in electronic product like cell phones, drones, computers, audiovisual equipment, etc.

The selection of suitable materials is a crucial step in medical device design and influences the safety and performance of medical devices.

Polypropylene (PP) – It is a durable and flexible material that can be used for various medical applications such as syringes, specimen bottles, pans, vials, and pill dispensers. More advantages include chemical resistance, steam sterilization, and anti-bacteria, which are important qualities needed for medical supplies present in a health facility.

Polycarbonate (PC) – It’s inherent strength, excellent optical clarity, high heat distortion temperature, and dimensional stability make it an ideal material choice for demanding, critical healthcare applications including thin-walled parts, surgical instruments, drug delivery systems, hemodialysis membranes, blood reservoirs, and blood filters. PC also can withstand gamma rays for proper sterilization.

Polysulfone (PSU) – PSU offers goods toughness and strength along with excellent dimensional stability. It is commonly used in neurovascular, cardiovascular, and drug delivery applications. It performs well even under the most rigorous sterilization methods, including steam, radiation, and ethylene oxide, and vaporized hydrogen peroxide.

PEEK – Medical devices made out PEEK offer superior fatigue properties and low moisture absorption, which is critical in implantable devices. PEEK components are also more compatible with diagnostic imaging with no artifacts. Some grades of PEEK are radiolucent. Biocompatibility and biostability of load-bearing medical implants is another critical area in which PEEK excels. PEEK can also be manufactured using many different methods such as CNC machining and injection molding.

Stainless Steel – With its diverse range of grades, stainless steel serves in a myriad of medical applications. From surgical trays to sterilization equipment and medical tubing, stainless steel proves its versatility. A particularly hard, tough and strong stainless steel, 17-4 PH stainless steel is used in the manufacturing of various non-implantable medical devices such as diagnostic equipment, support devices, and therapy instruments. Its excellent corrosion resistance and durability make it a preferred choice for these critical applications.

Aluminum – Aluminum devices are often utilized for orthopedic, endoscopic, spinal, trauma and surgical scenarios. That is in addition to non-specialized hospital equipment, including trays, bedpans, containers, and cases. Aluminum is lighter weight than stainless steel and more durable and hygienic than most plastics.

Simply click on the Request A Quote button and follow the instructions.

You will usually receive our quotation within 24 hours.

Place an order. We can help you easily handle all the requirements.

We start the job and deliver the parts to you on schedule, just as we promised.

Upload CAD files and submit the important details about your project.

Get quote with DFM analysis within 1 day.

Confirm Quote and Manufacturing Begins.

Qualified parts are delivered straight to your doorstep.