- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

With a full suite of manufacturing services available, APT is your ideal source for all your component fabrication needs.

+86 18814246095

APT continuously scales its offerings, delivering an ever-expanding menu of manufacturing capabilities

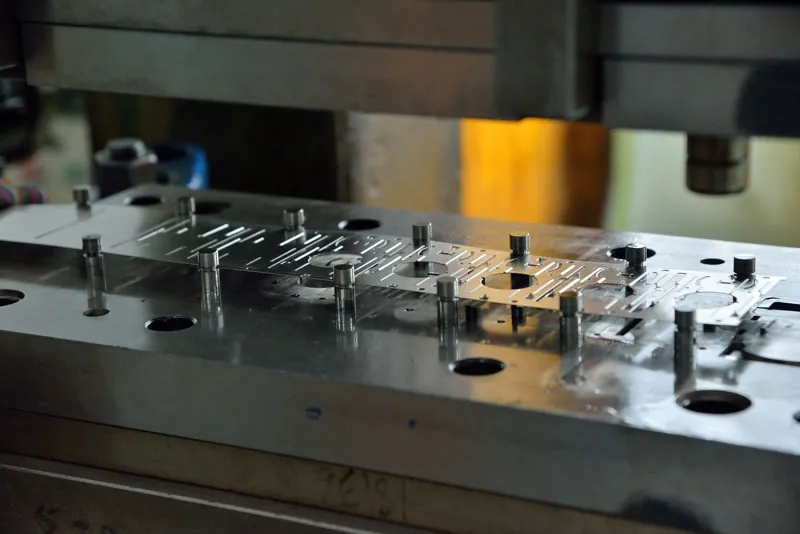

Injection Molding

Injection molding offers solutions with unparallel efficiency and cost-effectiveness for consumer goods that meet high-quality standards while optimizing production timelines.

CNC Machining

Technology-enabled CNC machining processes can accelerate manufacturing cycles, lower development costs, and help support product customization that consumers now demand.

Vacuum Casting

From show-room quality display models to end-use products, vacuum casting accelerates product development and market introduction.

Sheet Metal

The durability and versatility of sheet metal make it a common and critical technique widely used in electronic product like cell phones, drones, computers, audiovisual equipment, etc.

Find the right material to build up your selling points for a product to grab consumers’ attention, whether it is the price point, the performance, the exterior appearance or something else entirely.

Stainless steel – One of the best and most well-know characteristics of stainless steel is that it is extremely corrosion resistant. Its fire and heat resistance, hygiene, impact resistance and strength, aesthetic appearance, sustainability and long-term value has makes it an ideal choice for numerous consumer products like kitchen utensils, low-temperature applications and more.

Aluminum – Its superior properties in strength, light weight and applicability make aluminum an excellent material for hundreds of everyday products. This material can be machined or formed through sheet metal fabrication to create housings, brackets, or other metal parts that need high strength and low weight are required.

Copper – As the first metal humans discovered, copper is prized for its many useful properties, electrical/heat conductivity, durability, anti-bacteria and more, making the copper and copper-based alloys an good choice for jewelry, kitchen sink, music instruments, door knobs and pull handles, etc.

ABS – This reliable thermoplastic is known for its versatility, durability, and ease of processing, it is widely used in industries like consumer product. It brings general-purpose performance for parts like electronics enclosures and handheld devices, and is also relatively inexpensive.

Polycarbonate (PC) – This exceptionally strong, extremely impact resistant and UV protective thermoplastic has a low shrinkage and good dimensional stability. It’s a transparent plastic that is available in optically clear grades, which works well for transparent covers and housings.

Elastomers – Available in both vacuum casting and injection molding, this material has become essential in numerous industries and applications. It is chosen from several elastomeric materials for parts that need impact resistance or flexibility. Overmolding is also available for components and products with ergonomic grips, buttons, or handles.

Polyethylene (PE) – One of the most common plastics used due to its low cost and excellent chemical resistance. It also offers flexibility, strength, and toughness and can withstand low temperatures better than other plastics.

Polypropylene (PP) – It is often chosen for its excellent resistance to acids, bases, and organic solvents. It is also very durable and can be used in various applications.

Nylon (PA) – Nylon is popular for its high strength, dimensional stability, and low friction properties. It is often used for parts requiring good mechanical properties and chemical resistance.

Acrylonitrile Butadiene Styrene (ABS) – ABS offers outstanding toughness and has excellent heat distortion temperature properties. It is also very easy to machine and dye so that it can be used for various decorative and functional applications.

Simply click on the Request A Quote button and follow the instructions.

You will usually receive our quotation within 24 hours.

Place an order. We can help you easily handle all the requirements.

We start the job and deliver the parts to you on schedule, just as we promised.

Upload CAD files and submit the important details about your project.

Get quote with DFM analysis within 1 day.

Confirm Quote and Manufacturing Begins.

Qualified parts are delivered straight to your doorstep.