The current demand for innovative products and stiff competition in the market has led manufacturers to find methods to produce products in the shortest possible time. And the burden does not fall solely on manufacturing. It also focuses on the design process. It needs to be swift and, at the same time, inexpensive. That is where rapid prototyping comes in.

Rapid prototyping involves producing a sample or a test product in a short period. This allows designers and engineers to have proof of concept and verify whether the production process is on the right track. With the word rapid, you already have a clue on what the style of production would be. It is to be basic, fast, and cheap. Suffice it to say, rapid prototyping is an inexpensive way to validate the idea in the creation process.

Table of Contents

ToggleTakeaways from Rapid Prototyping

To manufacture a product in the shortest time possible and inexpensively, the design and prototyping process needs to be at a minimum. Traditional prototyping methods would take weeks or months to complete. But with rapid prototyping, the amount of time of the design process will be reduced, thus resulting in cost savings.

The key takeaway with rapid prototyping is that the product designers will have a prototype that users can validate. It will steer the direction of the design, allowing iterations that are valuable to the users.

How Does Rapid Prototyping Work?

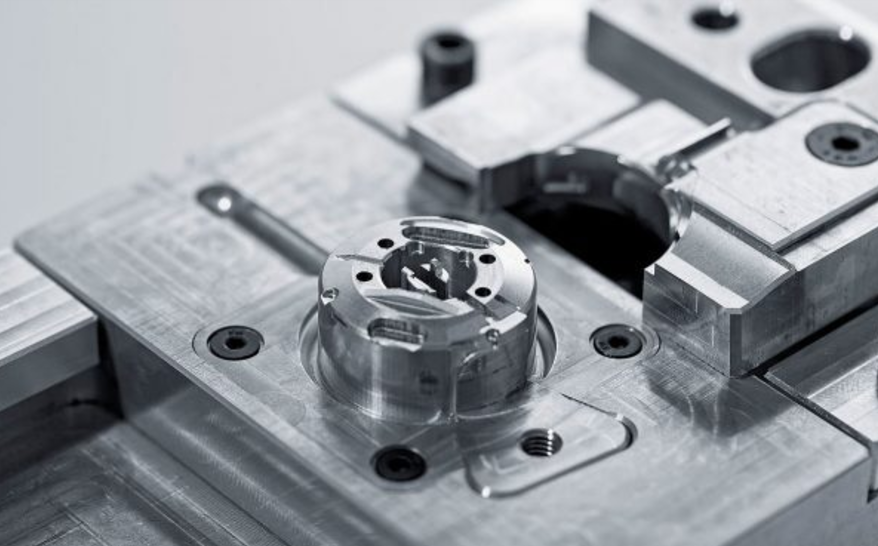

Rapid Prototyping begins with the design team creating samples of workflows and identifying the additive process to use. The materials for the additive process include thermoplastic, photopolymer, and adhesives. Compared with the subtractive and compressive methods used in conventional prototyping, the process builds the object by joining the layers or particles of the materials.

The rapid prototyping process involves three steps: prototype, review, and refine. In prototyping, the designer’s idea is transformed into mockups while keeping the standards, user experience, and best practices in mind. This prototype is shared with the users to evaluate whether it meets their needs and expectations. Based on the feedback, the designer identifies the areas for improvement and repeats the process.

When there is a difference between the stakeholder’s review and the user’s test feedback, the designers will return to the drawing board and guide the product development in the right direction until they have the product that meets the needs of the user and the business goals.

Benefits From Rapid Prototyping

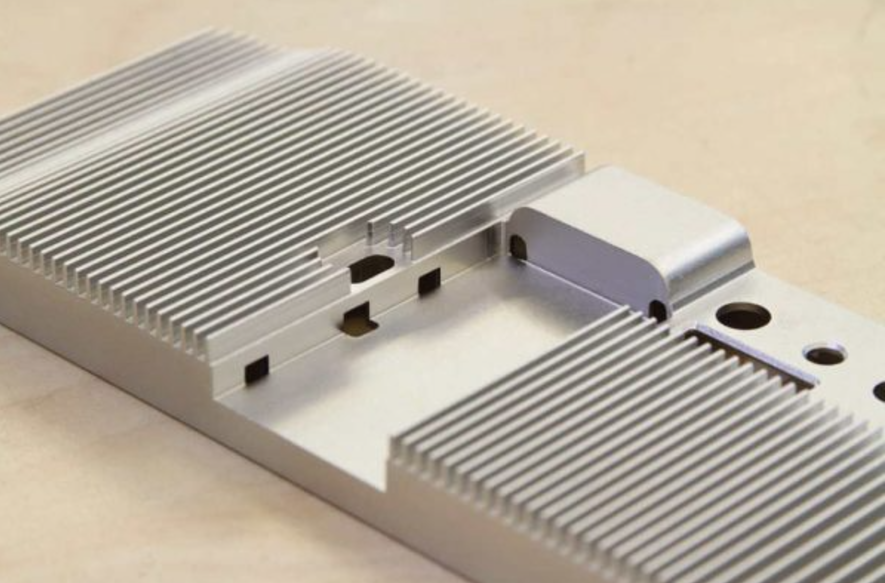

Prototypes provide handy communication tools for designers and engineers. It serves as a visual medium that can help the viewers understand the concept better than a one-dimensional image. It helps them get the right feedback for the design team to follow the right direction.

Since they have a three-dimensional representation of the concept, the development team can demonstrate the concept making it easier to understand compared to worded documentations. Rapid prototyping makes it effortless and time-saving for all the stakeholders.

Other than these benefits, prototyping also offers a huge creative advantage design team. It facilitates experimentation and brainstorming resulting in intelligent products.

With plenty of prototyping techniques to choose from, you can pick the right one based on the project at hand, the budget, and the stage of development.