One of the most overlooked factors that most clients and manufacturers fail to factor in is proper care and maintenance. For your machine to work properly maintenance is vital to keep your machines in excellent working conditions.

Maintenance is important to enhance the lifespan and durability of any working device or machine, additionally, it reduces the overall cost associated with repairs of your machine which makes the whole production economical and cost-effective.

For CNC prototyping machines, maintenance is critical and should not be overlooked. Overlooking care and maintenance will be very detrimental to your whole production process. For those with big business and largescale production, it’s almost impossible not to carry out regular maintenance.

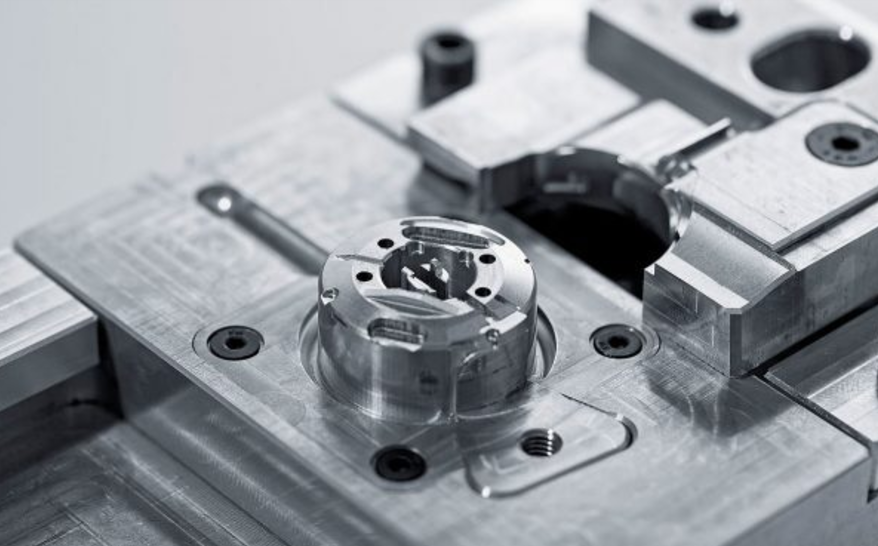

The good part is most CNC prototyping machines come with easy maintenance highlights and features, the machining spare parts are easily maintainable keeping your machines healthy and clean.

But just with machines, we can’t know everything all the time, for this post we are going to highlight some of the most overlooked but essential tips, continue reading to know more!

Table of Contents

ToggleThe hiring of skilled maintenance experts

We know how in-house maintenance can pose a bit of a problem, then you can start thinking of CNC prototyping maintenance experts, the experts have proper skills, techniques, and the technological know-how to carry out thorough and extensive maintenance work.

Thus, it’s vital to take your time when looking for the prototyping experts as they will contribute to the overall success of your manufacturing process as well as the products.

Greasing of the CNC prototyping machines regularly

The greasing of the machines regularly will ensure all the machine parts work well and swiftly ensuring there is no hitch in the production process. Currently, there is a wide range of products on the market which you can use when it comes to greasing of your machines.

Using the right fluids of your prototyping machines

When you have incorporated CNC machines into your manufacturing process, it’s vital to always use proper fluids and always check them regularly. These machines depend heavily on the fluids used.

You should always check on the fluids level regularly, keeping everything healthy and in good working conditions.

Always keep track of the breakdowns

Its always recommended keeping track of all the breakdown of your prototyping machines. Having proper records of all the parts will give you a rough idea of which machine parts are likely to breakdown in the future.

It will also enable you to assess the extent to which ensures that if it happens you will be in a better position to deal with the damage or breakdown.

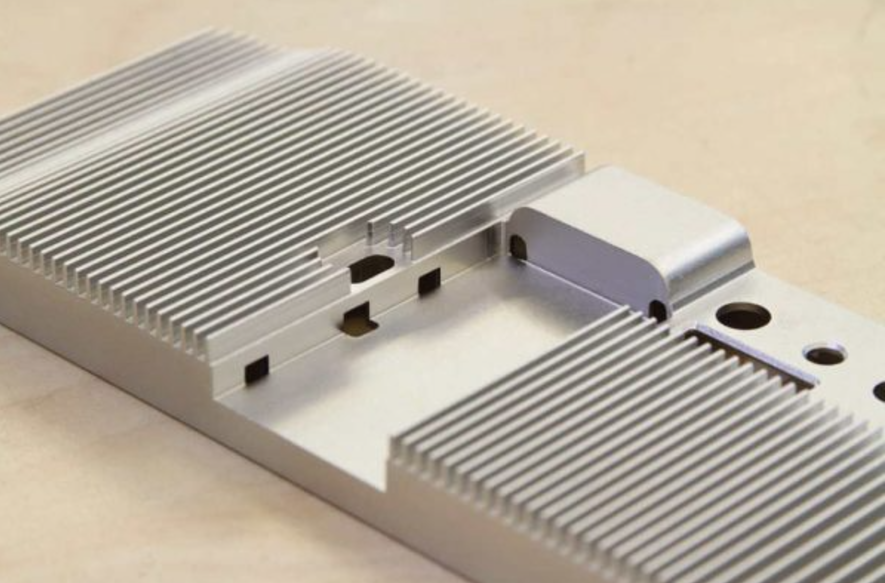

Buying you machine spare parts in advance

To ensure the non-stop CNC prototyping process, it’s advised to always have spare parts beforehand for easy replacement of the damaged parts. In my view, one of the major care and maintenance tips. Being able to plan prior to the damage will save you a lot of time and money.