CNC prototyping has gained huge traction in recent years as the go-to manufacturing process, not only will the technique enable both manufacturers and clients to cut down on the overall production cost but also improve efficiency.

There are plenty of prototyping machining companies worldwide, thus it’s imperative to always do a bit of research yourself to get a good feel of the firm you are looking for and whether they will be the right fit for you. Engage them, ask them all the questions to see if they will meet all your needs and requirements.

But, the most important question that is on everyone’s mind is how do you choose the right prototype machining firm? For those who have been wondering or asking themselves, you’ve come to the right place. In this article, we are going to discuss all the factors and features that would lead to you choose the right firm for your project.

Table of Contents

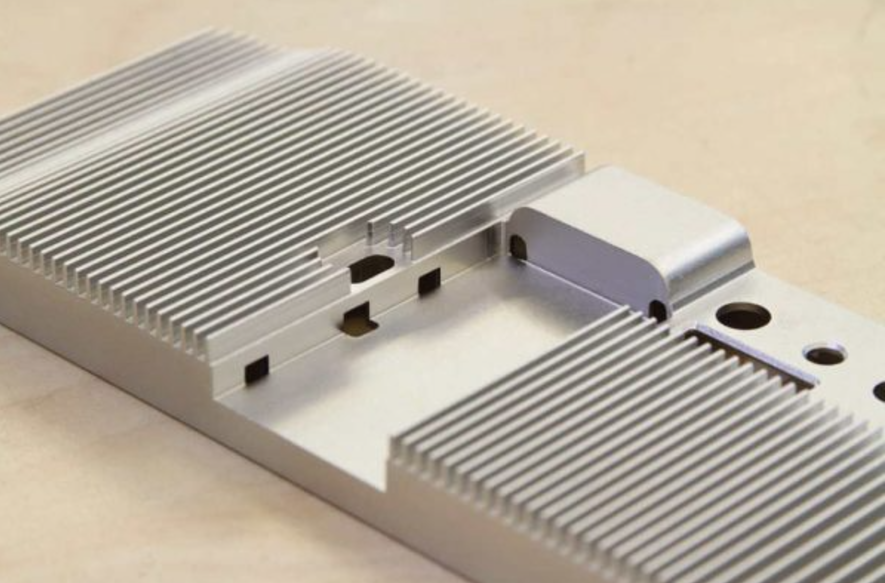

ToggleThe flexibility and versatility of the machining service

When you are in the market for a machining company, versatility should always be at the top of your list. Always go with a company that is not rigid and have a bit of flexibility with regards to factoring your needs, budget, and deadlines.

For the success of your project, you’ll also require a company that will advise you accordingly and gives you recommendations on which type of parts and raw-materials you’ll need to complement both the personnel and the project itself.

Also, they should be able to try out new and exciting machining techniques while maintaining high standards and quality. One thing that you should pay special attention to is to evade firms that has logistical problems, a proper prototyping firm will increase the rate of production so that you get your product on time, thus reaching the market faster.

Researching on past projects

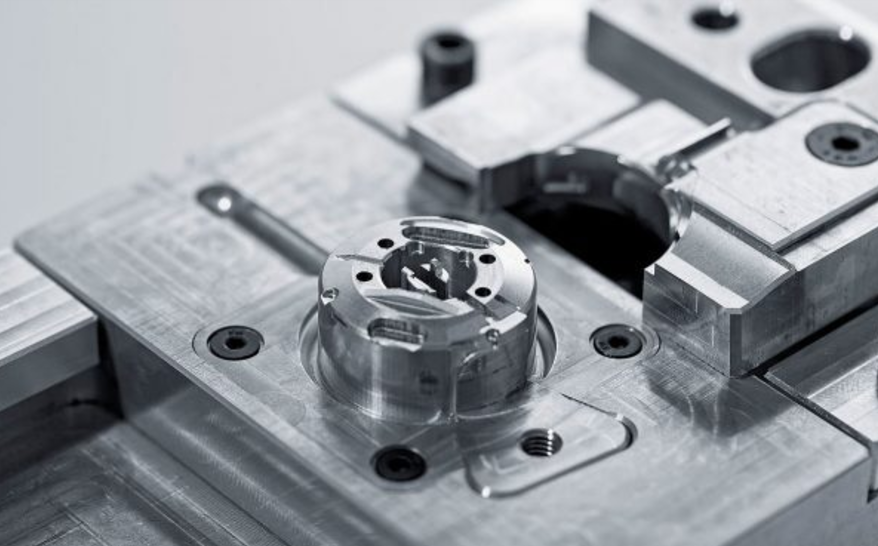

Regardless of the project that you want done, the firm has the blueprint of the parts and components to be created. The firm can utilize this blueprint to make your prototype before the rolling out of full production.

As a new client, extensively examine this prototype to single out any defects, it doesn’t harm to enquire about the previous work of the firm and their interaction with customers. With your budget, this should be enough to make high-grade and quality machined parts and products that will prove to be a hit on the market.

Being involved in the prototype machining process

Over the design phase, its always a wise thing to factor in the tow crucial aspect, what this means is the product will have to meet the client’s specification but also be produced within the set-out budget.

So, it’s imperative to go with a prototype machining firm that’s easier to get along with and work with. You can use the prototyping process to see if it easy to work with the firm, if they meet all the set requirements through the entire production process then that’s the right firm for you.