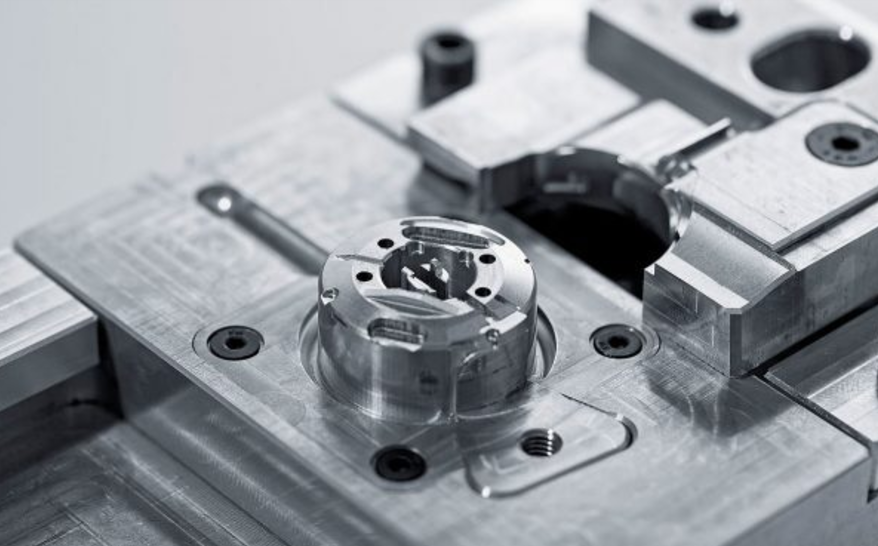

The term rapid tooling is used to describe a particular process that uses rapid prototyping that is the RT technique as well as to create a mold quickly. The use of the rapid prototyping process is a directly fabricated tool that is a limited volume of prototypes. So basically it takes the last date to link time as well as cost as per reason to a conventional tool. Apart from this, it is used to make multiple parts from alternative materials. So you have to consider the RT process, you have to justify the Rapid tooling process that includes the following things:

- Composite injection

- Silicone vacuum cast

- Zinc and Aluminium plaster

- Cast metal injection sand cast

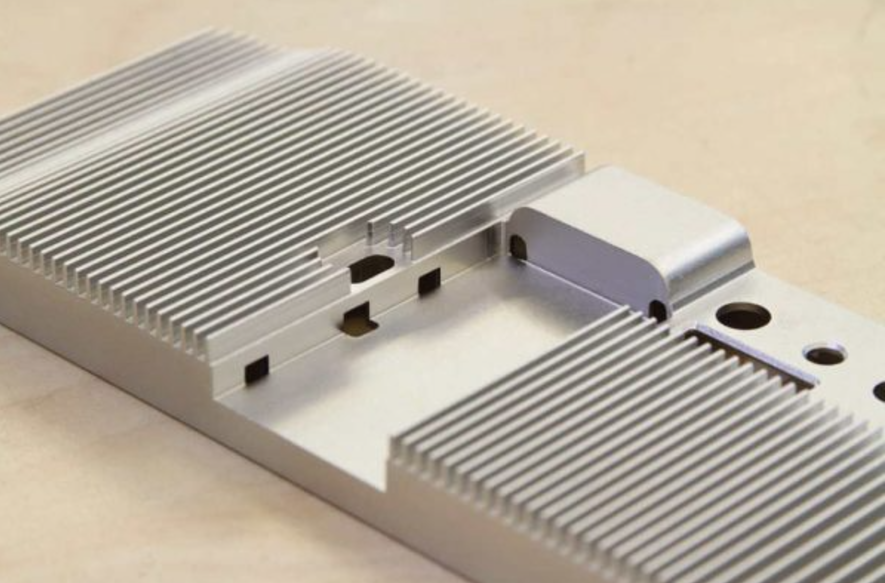

These days rapid tooling becomes a new model for the industry. So basically it is used as a prototype tool in that is mainly useful low volume production service that is a part of this. It is depending on the part of the design and the choice of the material that is going to be injected. There can be numerous parts that are going to develop through the help of this technique. The Rapid prototype tooling services offer free size models very fastly and include high speed dealing capability. It also includes numerous IT machines that can easily round up to 42000 and get a tolerance range of 0.0002.

When it comes to the accuracy of the method then it is a very rapid type of prototyping equipment that is going to use for the rapid tooling. It is just not about the process but it offers very fast results that can easily be achieved and surely offer you great success regarding the work.

Table of Contents

ToggleHow to identify design and opportunities in the process?

Do you think that material specification surely fits into your application? Not everyone has the perfect knowledge regarding the materials. So basically an expert can easily identify it especially when it comes to considering plastic. As you know the plastic industry is going to change with new developments in advance. However, as like most other materials you usually need to fit your needs better in comparison to others. It is very important to consider the custom-blended materials that carry along with the best team and higher prices intimate. Do not forget to contact the best supplier. If you have different types of questions about your material specification then you can get a rapid tooling provider that helps to get a perfect knowledge base and experience regarding the development field.

You have to identify the functions and areas that are expecting reliance tolerances

Most of the time it is about having a path created for the rapid tooling designers. It can easily send 3D data information to your form. It doesn’t include any type of dimensional information. You need to try to be realistic when it comes to specifying tolerance brands that work on the plastic parts, unlike the machined parts. You have to consider different molded components that include more variables in the production process.