You must be wandering online to get to know the fastest way to market your product. If yes, your search is over. You are on the right page to know about the process that can be useful for manufacturers to manufacture their products faster and compete with their competitors.

Rapid tooling is one of the best methods to manufacture products by saving time. You may have heard about it by other names including, prototype mold, soft tooling, and prototype tooling. Practically, it is a kind of injection that enables you to produce different parts easily and check their validity.

Keep reading to know more about the prototyping process and the advantages of this technique. Let’s know about it in detail.

Table of Contents

ToggleWhat is Rapid Tooling?

When conventional tooling and rapid prototyping methods are used together to manufacture any part quickly, the procedure is referred to as rapid tooling.

In other words, it is an effective way to manufacture and test the validity of the products before their marketing.

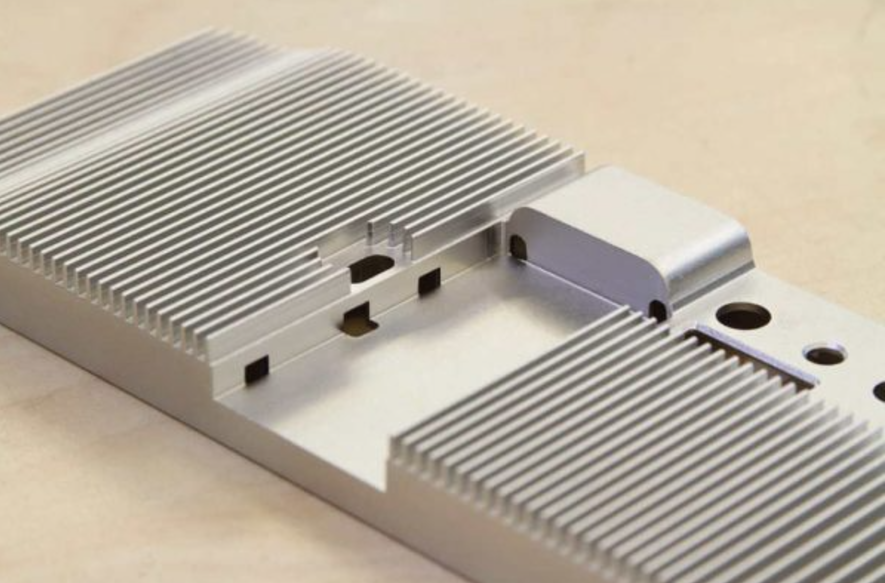

It is used to manufacture injection molded parts. This is more cost-effective as compared to conventional procedures.

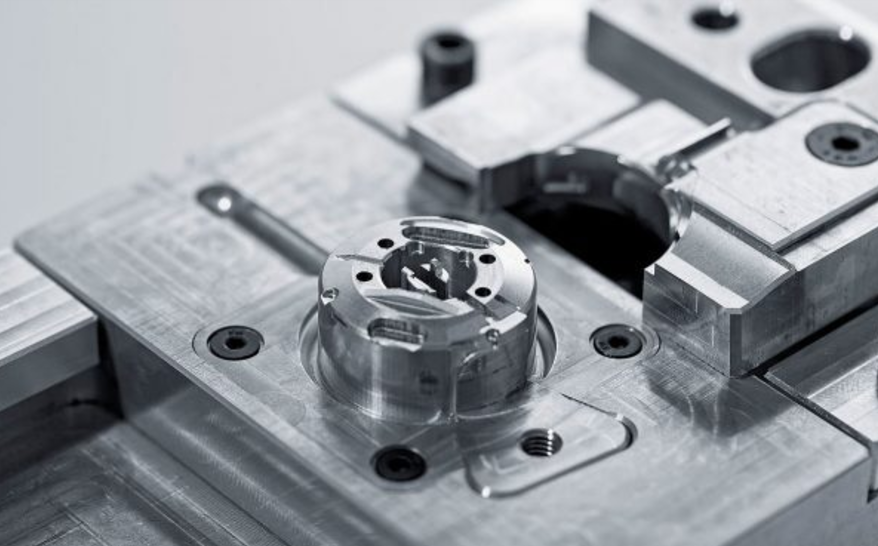

Rapid tooling was started in 1990 when engineers used plastic injection molding to check if they can manufacture molds without investing weeks and months. Cavities, Cores, and side actions of the part can be built easily with this method.

Different rapid tooling techniques are available but their benefits differ according to the technology, accuracy, consistency, used materials, and sizes.

How does it work?

It is widely used to manufacture injection molded parts. The most familiar examples of injection molding are bottle caps, medical syringes, and Lego bricks.

This process has three main components including, machine mold, raw plastic, and injection machine mold. In this process, the raw plastic is melted, and then it is molded in the machined mold by injecting the melted plastic into it where it is cooled and comes to the final form.

These parts are removed once they are cooled.

Materials used in rapid tooling:

Nylon GF’S:

It is a thermoplastic that has good abrasion resistance and mechanical properties. It is strengthened with glass fibers. The nylon may contain 30% or 40% GF.

Polypropylene or PP:

Polypropylene is a widely used material in rapid tooling and injection molding. It also contains resistivity against chemicals.

ABS:

It is also a kind of thermoplastic with great resistance properties and low density. Like nylon GF’S it is also armored with glass fibers.

PA6 and PA12:

PA6 and PA12 both are high-performance plastics. PA6 contains great toughness and surface finish properties. On the other hand, PA12 has properties like low absorption of moisture, flexibility, and strength.

High-Density Polyethylene or HDPE:

It has high resistance, long-lasting property, and great strength to density ratio.

Low-Density Polyethylene or LDPE:

It is flexible and also contains high resistance properties. It is light in weight but high in strength.

Polyoxymethylene or POM:

It can resist high temperatures and has resistance against chemical abrasions. It also possesses high dimensional stability.