Table of Contents

ToggleWhat is a prototype mold?

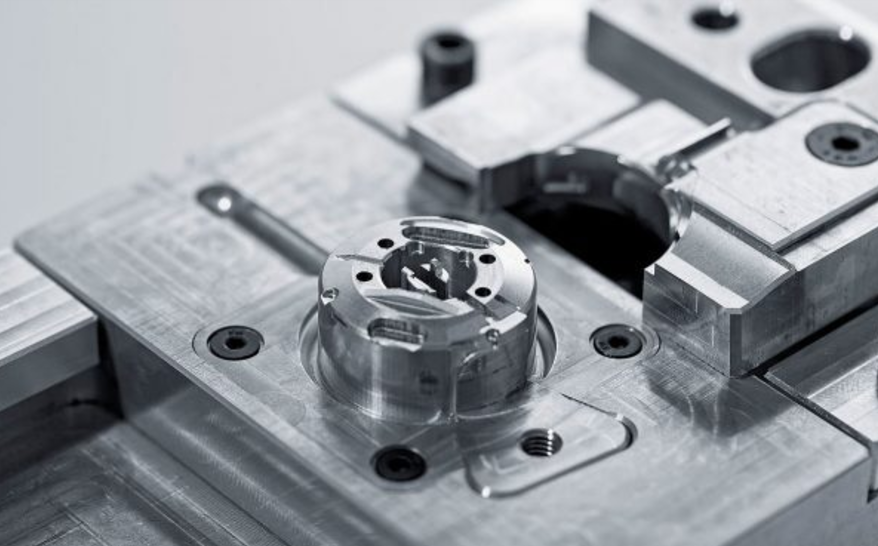

Prototype molds play a key role in the manufacturing and production sector, they build a gap and form links between different ideas and elements that are being fused or being brought to light. The plastic injection molds are majorly used in the different technical functioning and also real injection form a part of it.

Designers and engineers have greatly benefited from prototype molding bridges tooling allowing them to manufacture a gap that arises between two tools retreated to the production system and activities.

Prototype molding is quite popular within the engineering department, the production technique is quite reliable compared to other manufacturing processes. If you are looking to make a possible mold of any type of gaps between these two tools, then the functionality of these molds will assist you to understand the testing form of their use.

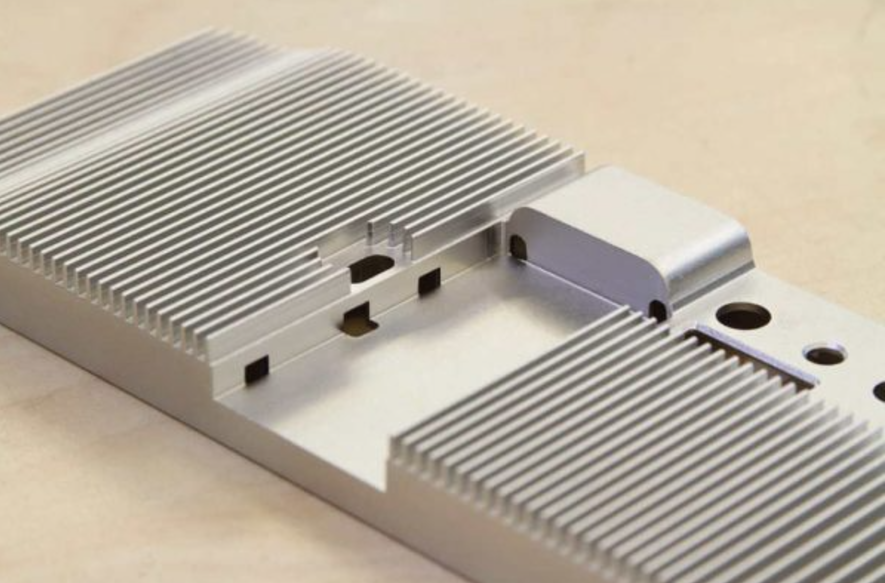

The molds are also used for specific and current use, they are mainly chosen with regards to their color and performance functions. The surface finish is usually attached which allows the engineers to fully use them to their advantage and understand which service has a far better and excellent server for different designs and creating technical contents for assignments.

How useful are these molds?

There are a wide variety of benefits that comes with prototype molds, hence their popularity. When you are thinking about making a new part or product, there are additional tooling cost and expenses makes the whole project unprofitable.

With the help of prototype molding, some of these hurdles can be avoided easily, plus it also comes with additional benefits. Talk about killing two birds with one stone.

Assist in recreation and modeling

Plastic molds are crucial when it comes to modeling bringing all your ideas to light, the sole approach that you can take when it comes to any engineering tool is the type of service you generate towards it.

This specific molding enables you to exactly pinpoint which components or elements will be the right fit for your model. Plus, there are numerous tests and experimentation conducted through which you can understand which part of the prototype molding can be used and can be helpful for service.

Assist in quick succession of molds

Prototype molds can help you make your desired prototype with limited finances or budget. In this way, fast-paced businesses or firms will have a huge advantage and a much smoother compared to the original.

Cavities solely meant for pulling ahead

These types of molding will specifically help you to bring in an approach that is mostly used and widely preferable. There are a wide variety of cavities present inside a product that can only be functioned when they are being pulled away by separate holes and their elements.

This type of force plus their parts will assist you to solve the problem seamlessly and straightforwardly and it will also enable you to understand the subsequent cavities which are created with the prototype model.