CNC machining may not be a common term to many people, especially the ones who have never been in the production industry. CNC machining services have for so long been the hallmark in the production of top-notch products from the building industry, medical sector, and transport sector to the automobile sector. Many people like the fact that they don’t have to contact original manufacturers for products or spare parts produced. All they need to do is to have a prototype of the part they want and it would be produced. Here are some of the basics of CNC machining worth knowing.

Table of Contents

ToggleComputer Numerical Control

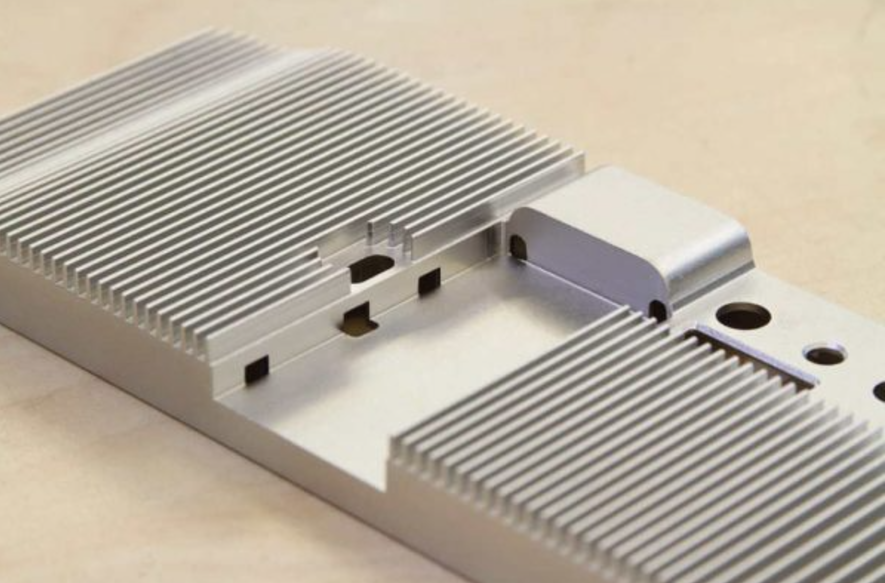

This is a term that means computers are used to control machines. This means a design is fed into a computer and this design has to be actualized through machines. It is not just the design but even the quality benchmarks are set in the computer such that any deviation of the quality would trigger an alert system. These alert systems serve to ensure that the right process is followed to prevent the production of counterfeit products. Computers control the machine so there is very little room for error and wastage of resources.

The Computer Software is Programmed Using G-Code Language

Unlike the other types of computers that commonly use Java, Django, and other basic programming languages, CNC machining services computers use the G-code language. This language enables the proper movement of tools and machines to ensure proper production of the goods has been achieved. When using G-code, it becomes easy to control the positions and speed of movement of the machines. This makes it easier for people to control the production speed of the machines. This programming language is chiefly used because it enhances the smooth production of the products without compromising quality.

Computer-Aided Design

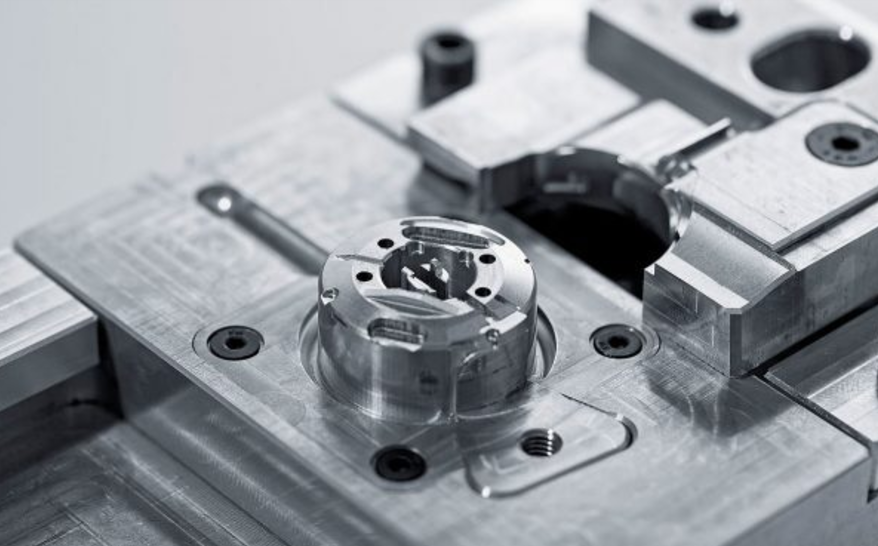

One of the reasons why there are minimal errors in the CNC machining is because of the CAD design. The process always begins with 3D designing which is normally in the computer. This is where the G-code is derived from and then before the production process begins, there is a trial that is carried out to ensure every aspect of the design is perfect. The trial process is known as cutting which aims at showcasing any mistakes so that they are removed early enough. After this process, the actual product is then produced for the end-user.

There is No Room for Mistakes

Compared to manual machining, CNC machining is always more reliable. Even with complicated designs, the CAD ensures that everything is put into the perfect order before actual production begins. This way, you will have realized that there are no problems with the end part. For mass production of products or parts, this CNC machining is the best to use.

Conclusion

CNC machining is the place that people run to when they need parts or products manufactured for them. You can design anything and use any material to make your product. Most people with cars who have had a problem accessing manufacturer parts normally go to these industries to have the parts they want.