- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

APT-Mold, established in 2017, is a high-quality manufacturing company located in Southern China, specialized in the manufacture of rapid prototyping, CNC machining, plastic injection molding, compression molding and pressure die casting. Products are widely used in automobile, medical device, home appliance, consumer & commercial products., etc.

APT’s manufacturing services are structured for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

APT assures the quality of your parts with our ISO 9001:2015 and IATF 16949:2016 certified quality management system.

After you upload CAD files and submit project details, we will provide a quote with fast lead time and very competitive price within 24 hours, no MOQ required.

Our very capable engineers will analyze your part geometry to identify any features that may be difficult to machine or mold, and help with trouble shooting by providing you with innovative solutions.

Our highly qualified machine shops can make any custom design, simple or complex. We offer rapid machining, rapid tooling, small-batch and high-volume production.

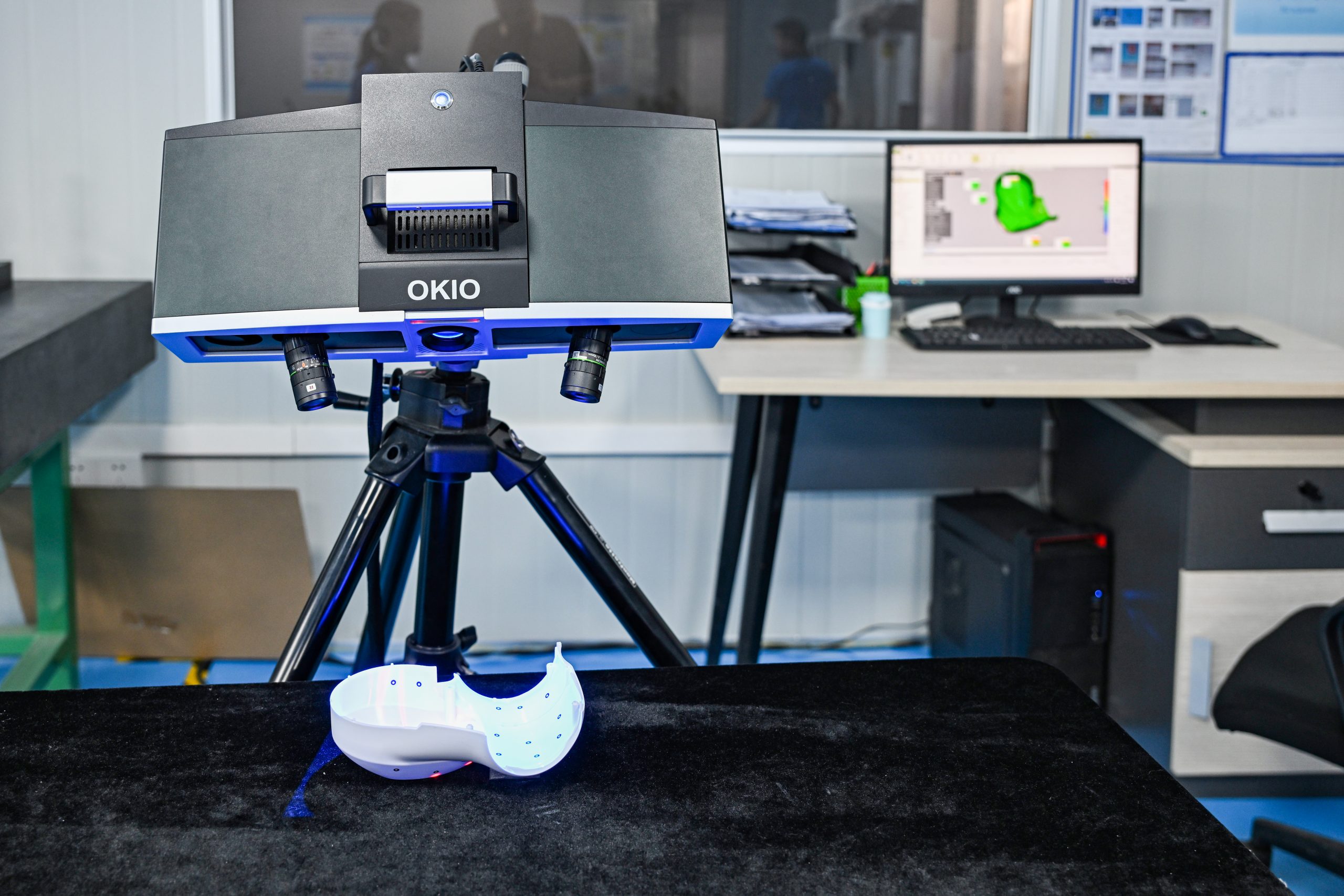

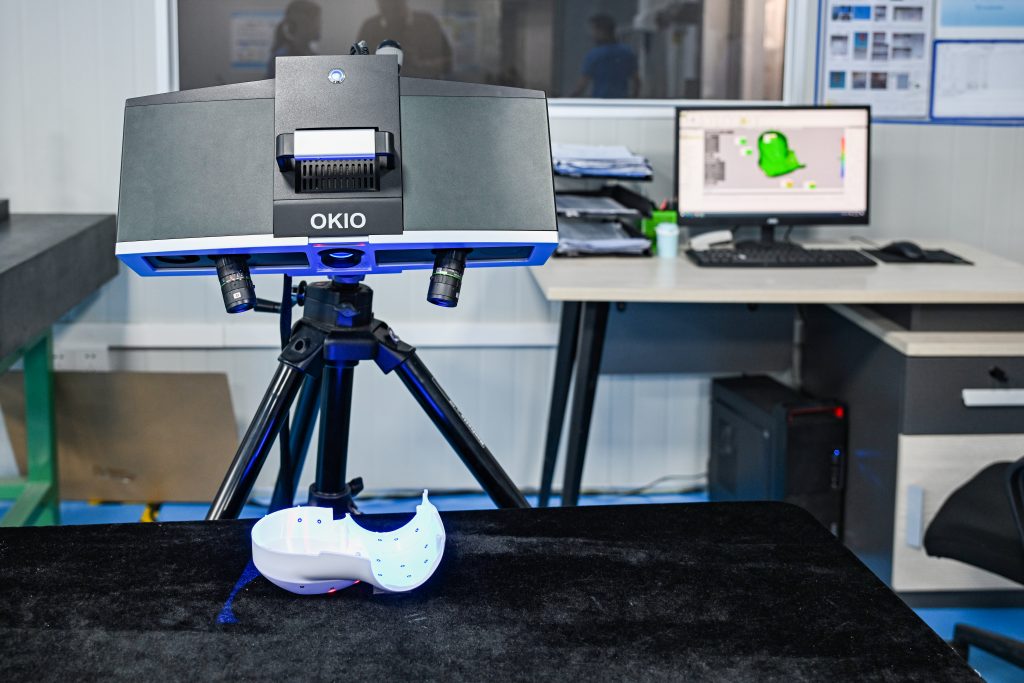

We perform inspections at every step of the product development journey, from incoming material verification, first article inspection, in-process and final inspection to meet your regulatory and performance goals.

From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

APT’s manufacturing services are structured for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

APT assures the quality of your parts with our ISO 9001:2015 and IATF 16949:2016 certified quality management system.

After you upload CAD files and submit project details, we will provide a quote with fast lead time and very competitive price within 24 hours, no MOQ required.

Our very capable engineers will analyze your part geometry to identify any features that may be difficult to machine or mold, and help with trouble shooting by providing you with innovative solutions.

Our highly qualified machine shops can make any custom design, simple or complex. We offer rapid machining, rapid tooling, small-batch and high-volume production.

We perform inspections at every step of the product development journey, from incoming material verification, first article inspection, in-process and final inspection to meet your regulatory and performance goals.

From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

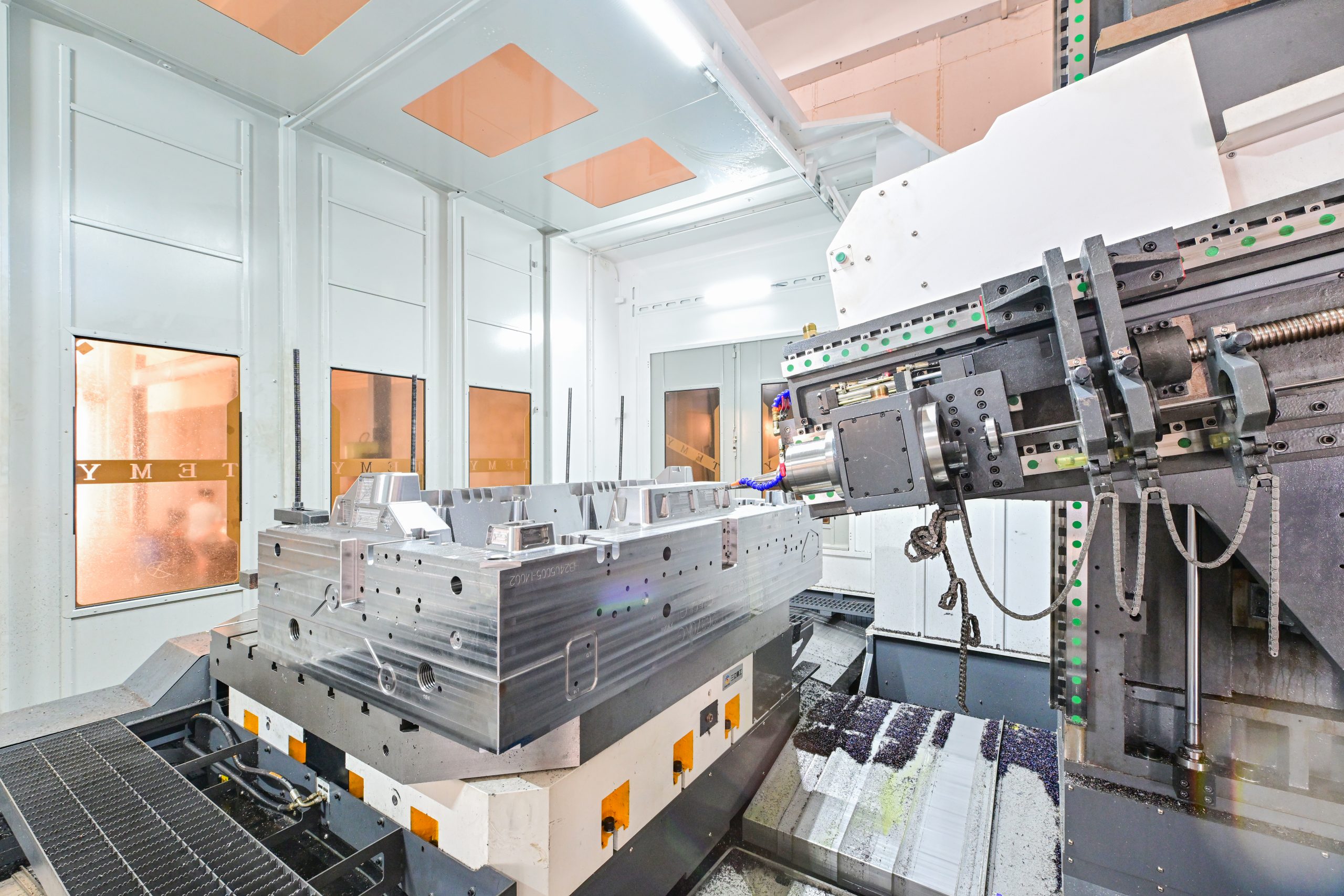

CNC machining is a subtractive manufacturing process that uses 3-axis, 4-axis and 5-axis milling, turning, or turn-mill compound processes to cut solid plastic and metal blocks into final parts.

APT’s CNC machining services are structured for speed, flexibility, and excellent quality no matter the volume of parts.

Polyurethane vacuum casting is often used as a substitute for plastic injection molding because it is ideal for small volume, the molds create up to 20 high-fidelity copies from the original master pattern.

We offer a complete solution for creating master patterns and cast copies based on your CAD designs along with a full line of finishing services such as painting, pad printing and more.

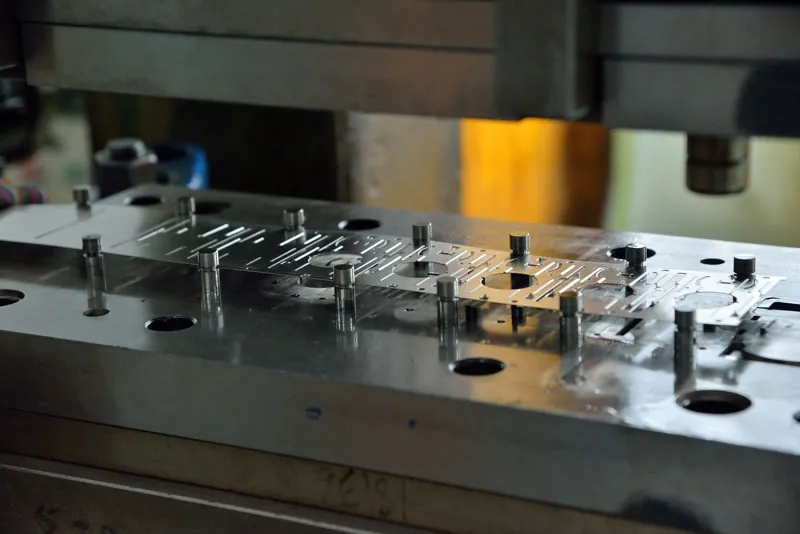

Plastic injection tooling makes precision-engineered molds used to shape molten plastic into desired components. These tools are essential for manufacturing a wide range of plastic parts with accuracy and consistency.

APT offers a wide variety of tooling solutions tailored to your project requirements, including cold/hot runner, single/multi-cavity, family molds, 2K mold, etc. aiming to support your prototype, low, middle or large volume of manufacturing with superior quality in a cost effective way.

Sheet metal is a comprehensive cold working process for metal sheets, including shearing, punching-cutting compounding, folding, riveting, splicing, forming, etc.

The efficiency and high precision of sheet metal fabrication, coupled with APT’s variety of materials, and post-processing options means you can get parts for automotive, energy, industrial, medical, consumer products, etc. hitting your goals just right.

3D printing or additive manufacturing is a process of making three dimensional objects from a digital file.

We are your one-stop shop for accurate, precise, custom 3D-printed parts at a competitive price. 3D printing works best for functional prototypes, complex designs, and as well as end-use applications.

Injection molding is a manufacturing process that consists of filling a metal mold cavity with liquid plastic resin, which then cools and forms a plastic part.

Our manufacturing experts are committed to providing you with the highest level of professional support for injection molding. APT adopts automated operations to magnifies the efficiency, consistency, bringing higher production rates. You’ll receive superior results while saving time and money.