Worried About How Well Your Product Is Or If It Has Any Faults? Go For Prototype Tooling

A prototype is a working model that helps us know

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

ISO 9001:2015 | IATF 16949

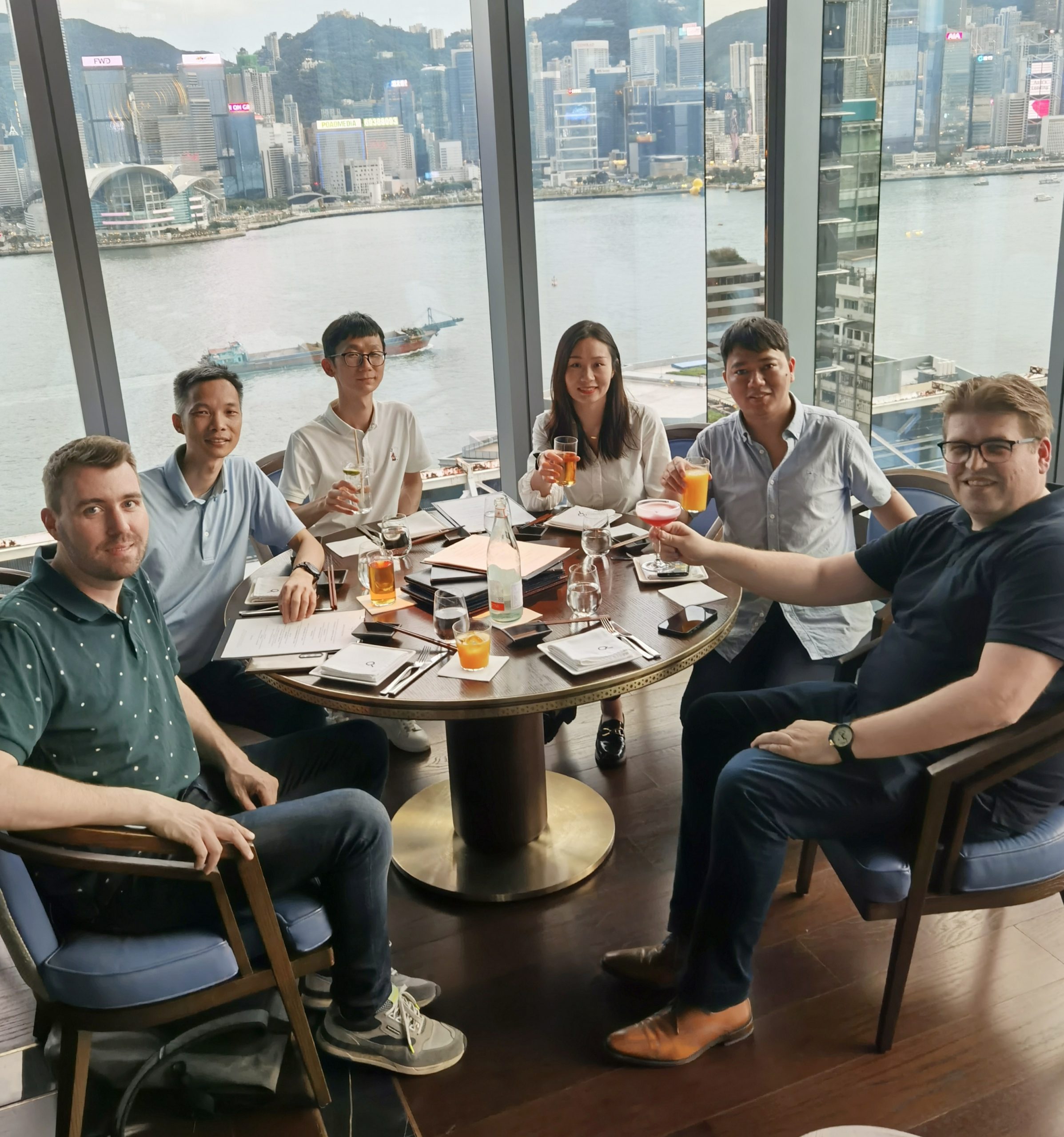

APT-Mold, established in 2017, is a high-quality manufacturing company located in Southern China, specialized in the manufacture of rapid prototyping, CNC machining, plastic injection molding, compression molding and pressure die casting. Products are widely used in automobile, medical device, home appliance, consumer & commercial products, etc.

APT prides itself on offering a high level of customized service to meet your exact needs. Our engineering team supports you at every step, from initial product development through to mass production.

CNC machining is a subtractive manufacturing process that uses 3-axis, 4-axis and 5-axis milling, turning, or turn-mill compound processes to cut solid plastic and metal blocks into final parts.

APT’s CNC machining services are structured for speed, flexibility, and excellent quality no matter the volume of parts.

Polyurethane vacuum casting is often used as a substitute for plastic injection molding because it is ideal for small volume, the molds create up to 20 high-fidelity copies from the original master pattern.

We offer a complete solution for creating master patterns and cast copies based on your CAD designs along with a full line of finishing services such as painting, pad printing and more.

Injection molding is a manufacturing process that consists of filling a metal mold cavity with liquid plastic resin, which then cools and forms a plastic part.

Our manufacturing experts are committed to providing you with the highest level of professional support for injection molding, and carry out a comprehensive design for manufacturing (DFM) review for every tool. You’ll receive superior results while saving time and money.

Sheet metal is a comprehensive cold working process for metal sheets, including shearing, punching-cutting compounding, folding, riveting, splicing, forming, etc.

The efficiency and high precision of sheet metal fabrication, coupled with APT’s variety of materials, and post-processing options means you can get parts for automotive, energy, industrial, medical, consumer products, etc. hitting your goals just right.

3D printing or additive manufacturing is a process of making three dimensional objects from a digital file.

We are your one-stop shop for accurate, precise, custom 3D-printed parts at a competitive price. 3D printing works best for functional prototypes, complex designs, and as well as end-use applications.

A variety of treatments adopted to improve your parts appearance, performance and durability including sanding, polishing, anodizing, painting, plating, pad & silkscreen printing and many more.

Whether in metal or plastic, from a one-off prototype to mass production, we have everything you need to take your project that final step to perfection.

CNC machining is a subtractive manufacturing process that uses 3-axis, 4-axis and 5-axis milling, turning, or turn-mill compound processes to cut solid plastic and metal blocks into final parts.

APT’s CNC machining services are structured for speed, flexibility, and excellent quality no matter the volume of parts.

Polyurethane vacuum casting is often used as a substitute for plastic injection molding because it is ideal for small volume, the molds create up to 20 high-fidelity copies from the original master pattern.

We offer a complete solution for creating master patterns and cast copies based on your CAD designs along with a full line of finishing services such as painting, pad printing and more.

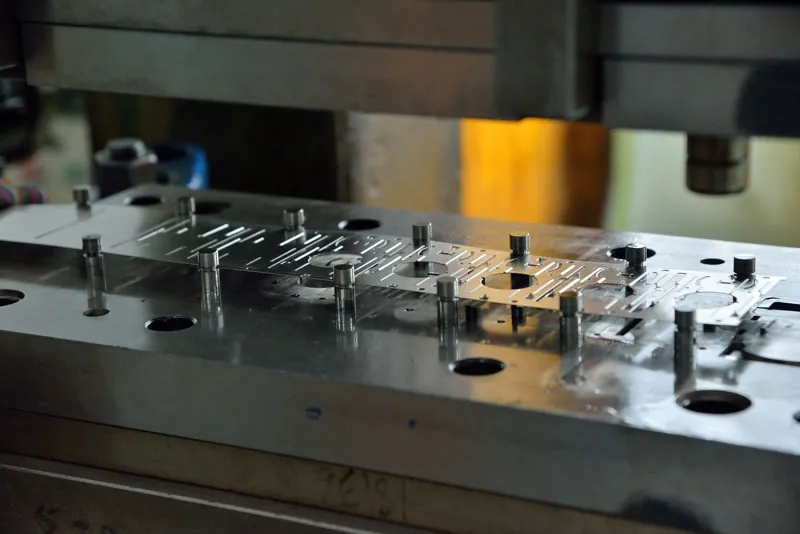

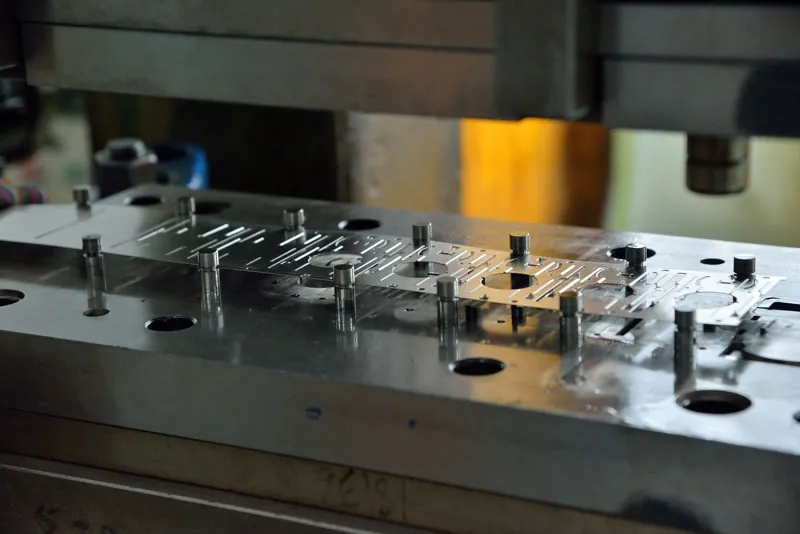

Plastic injection tooling makes precision-engineered molds used to shape molten plastic into desired components. These tools are essential for manufacturing a wide range of plastic parts with accuracy and consistency.

APT offers a wide variety of tooling solutions tailored to your project requirements, including cold/hot runner, single/multi-cavity, family molds, 2K mold, etc. aiming to support your prototype, low, middle or large volume of manufacturing with superior quality in a cost effective way.

Sheet metal is a comprehensive cold working process for metal sheets, including shearing, punching-cutting compounding, folding, riveting, splicing, forming, etc.

The efficiency and high precision of sheet metal fabrication, coupled with APT’s variety of materials, and post-processing options means you can get parts for automotive, energy, industrial, medical, consumer products, etc. hitting your goals just right.

3D printing or additive manufacturing is a process of making three dimensional objects from a digital file.

We are your one-stop shop for accurate, precise, custom 3D-printed parts at a competitive price. 3D printing works best for functional prototypes, complex designs, and as well as end-use applications.

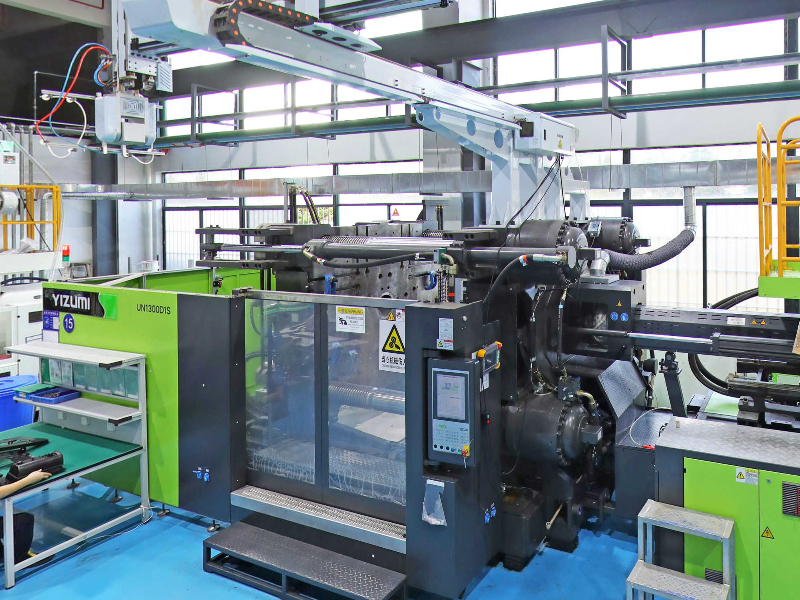

Injection molding is a manufacturing process that consists of filling a metal mold cavity with liquid plastic resin, which then cools and forms a plastic part.

Our manufacturing experts are committed to providing you with the highest level of professional support for injection molding. APT adopts automated operations to magnifies the efficiency, consistency, bringing higher production rates. You’ll receive superior results while saving time and money.

APT continuously scales its offerings, delivering an ever-expanding menu of manufacturing capabilities

Automotive

APT is IATF 16949:2016 certified and trusted by Tesla, Ford and some other world-class motor vehicle and parts companies

Medical and Healthcare

APT teams up with leading medical device makers, wearable tech innovators, suppliers, and research labs to accelerate rapid prototyping and continually scale manufacturing capacity

Consumer Products

With a full suite of manufacturing services available, APT is your ideal source for all your component fabrication needs.

Simply click on the Request A Quote button and follow the instructions.

You will usually receive our quotation within 24 hours.

Place an order. We can help you easily handle all the requirements.

We start the job and deliver the parts to you on schedule, just as we promised.

A prototype is a working model that helps us know

The word “Prototype” derives its origin from the Greek work

These days, there are a wide range of manufacturing technologies

These days, a wide range of prototype tooling options is

Rapid tooling is known as the name of prototype tooling. It

Right now, the need for getting prototype services in the market has

A prototype is a working model that helps us know

The word “Prototype” derives its origin from the Greek work

These days, there are a wide range of manufacturing technologies

These days, a wide range of prototype tooling options is

Rapid tooling is known as the name of prototype tooling. It

Right now, the need for getting prototype services in the market has